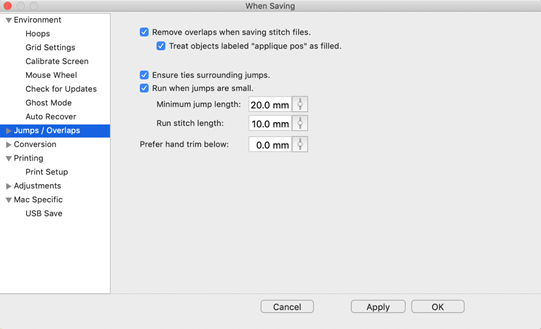

There are several operations that occurs during the process of saving a stitch file. These are displayed using the Preference Files>When Saving.

The ‘Remove overlaps…’ setting, better known as ‘Remove Hidden Stitches’ or ‘RHS’ will let the program run a process to remove stitches in one design that will be hidden by another design. This does not affect objects within a design, as those would naturally be hidden or not as dictated by the digitizer.

Removing overlaps allow you to merge designs onto the page with them touching or overlapping each other. This operation is common in graphics, but stitches are not graphics. Adding one design on top of another will cause excess density and can break needles, ruin projects and all the accompanying misery that comes with it. By removing those hidden stitches, using our patented method, you will find that your composition sews without the density headaches.

Overlapped appliques are even harder for software to handle. Where layering in stitches is a concern, layering of applique fabric has extra considerations. The program has color settings where the user can tell it that a certain color is a specific applique step. With this information, the program can avoid performing RHS on appliques, as necessary.

Jump stitches are created when, within a single color, the needle must travel across the design without sewing stitches. Jumps are normally trimmed by hand or machine. Sometimes there are merged designs which have jumps that the digitizer assumes will not be cut, such is the case with many commercial designs. When the digitizer decides not to cut the jump, they don’t usually leave a tie-off stitch, which prevents the thread from unravelling after the jump gets cut.

Ensuring that there are tie-offs on either side of a jump will allow you to cut those jumps even if the person digitizing the design hadn’t planned for it.

Jumps have other parameters, usually concerning commercial embroidery. For instance, an embroiderer may prefer to hand trim, or have the option to hand trim, small jumps. In commercial embroidery, these are often left untrimmed.

Sometimes jumps are short enough that the machine can place a stitch or two instead of jumping. This process, called, “nesting a stitch,” saves the machine operator time by not having to cut and not having the machine cut, which takes many seconds, cutting production efficiency. The setting, “Run when jumps are small” allows you to set the size of a jump that may be nested with stitches and the ‘Run stitch length’ controls how many nested stitches will be created. A short run stitch, such as 1.0mm, or even smaller, will nest well in most fabrics, but you don’t want a long run of small stitches, which is why the ‘Minimum Jump Length’ parameter is there.