So, you saw it on the Internet and had to have it.

But it’s too big for your machine…

Essentials and Enthusiast have our patented design splitting technology built into it. This system automatically splits designs into multiple positions for sewing as separate designs that tile together to make a larger design. In the past, splitting a design took hours of editing by a person schooled in the process.

Our splitting feature drastically reduces the visible ‘seams’ that occur from manually splitting files using an editor. In most cases, the final product is indistinguishable from one created on a larger-field machine.

Note: StitchArtist has multi-position hoops for the sole purpose of digitizing to accommodate them. You can digitize the design as a whole, and then separate designs and add alignment lines as needed. StitchArtist does not include auto-splitting of designs.

Some hoops have multiple positions. This means that you only hoop the fabric once and generate the design by sewing it in those multiple sections. However, you can achieve the same result by re-hooping the fabric multiple times to create the design. We call this a “Virtual Hoop.” The Essentials version of the program comes with many hoops and virtual hoops pre-defined. The Enthusiast version has creation and editing of these hoops as well.

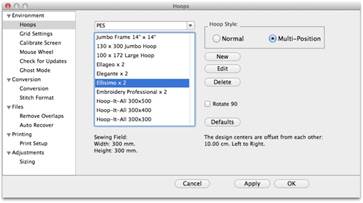

When sewing designs in multiple sections, often the question of alignment comes up. This is accomplished automatically with multi-position hoops, but to make it easier for regular hoops, the program will add basting stitches that will align the designs. To choose a hoop, click the preferences button on the toolbar, and the Hoops window will appear:

The Multi-Position hoops are separated from the Normal hoops, and you click on the Hoop Style to select the list you want to see. Here is the Jumbo Frame:

You’ll notice that this hoop has two rectangles that overlap in the middle. Each of these represents a sewing field. To make it more obvious which lines represent which field, the inside of each rectangle has a dotted line indicating the inside of the field.

If you are combining designs to make a composition, it is always going to give the best result if you keep whole designs into one region. This produces a split that will have the least effect on the actual stitches on the design. Of course, this is not necessary, however, as the design may be split even if it lies in the middle of the hoop, but some splitting would have to occur.

The ‘+’ marks shown indicate the centers of the sewing fields.

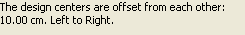

Note: If you look at the Hoop in the selection window you will see a note that the design centers are offset from each other. This means that when you sew the two sections, the centers of each design will be separated by that amount. This is your initial placement method for each design.

In order to position your design, it is always advisable to print an actual template of the design. This helps you visualize what it will look like once embroidered, and it will help define the center position of the design on the fabric. Once you have the center of the overall design, then you will want to mark the centers for the individual fields. In the example above, this would mean that you mark the fabric 5 cm. from the center on both the left and right of the design center. This places the two designs 10 cm. apart. This basic positioning will help you get the result onto the fabric where you want it to go.

Multiple Hooping is the process of creating a large embroidery design by re-hooping the fabric as you embroider each section. Multiple Hooping is an art that requires a complete understanding of what you are doing, as well as an excellent ability for placing your fabric in the hoop. It is not a method that should be practiced by the timid. You can split designs for Multiple Hooping by creating your own hoop:

Suppose you have a design that is 9 inches high and 8 inches wide. Also, suppose that your machine will embroider a region 9 inches high and 6 inches wide. (These are typical values for today’s machines.) What you want to do is to create a two-position hoop to accomplish the split.

Create a hoop that is 9 inches high, with two positions. The separation should be set to allow the greatest possible overlap between the two regions: 8 inches (desired) - 6 inches (a single hoop width) = 2 inches.

A separation of 2” would be the smallest possible for the desired 8-inch width, and would provide the greatest overlap of the regions.

Note: The use of columns allows side-by-side multiple-position hoops. It’s a lot of embroidering, but it looks good and can easily fill a jacket back.

It is very important to mark your fabric before embroidering. When the fabric is re-hooped it must be parallel and centered to the first hooping. Also, the distance between the centers needs to be precise. (This is 2 inches in this example.)

If it is possible, we encourage the use of ‘Floating’ techniques for hooping: not actually hooping the material itself, but rather hooping a stabilizer and attaching the fabric to it with adhesive and/or a basting stitch. This will provide the least distortion in the fabric while the overlapped regions of the design are being embroidered. One easy method, if your material can handle it, is to use carpet tape (double-sided and very sticky) on the bottom of your tightened hoop. This can then be perfectly aligned and pressed into place. (The adhesive comes off with a lot of water-soluble solvents and even soapy water will usually work.)

Remember:

It is a really good idea to take a class on this type of process to get the hang of it, and practice before moving on to an actual project!

When you save your files, the output files represent each region of your design.

The files are automatically given names indicating their stitching order as well as the position within the hoop. For instance, “Rose.Pes” may split into “Rose Top #1.Pes” and “Rose Bottom #2.Pes”.

Additionally, you may get a text file that explains the color sequence for your new files. In many designs, a color is only needed in one region. Where this is the case, that color will not exist in all the output files. To help reduce this “Color Confusion”, a text file is created with a table. The following is text from an example file:

“Roses.Pes

Your original file had 3 colors.

The program has split your file into 2 segments.

This cross-reference has been created for you because some thread colors in the original file were not needed in some of the split segments.

File: C:\Roses Top #1.PES

Color 1 = original color 1

Color 2 = original color 2

Color 3 = original color 3

Color 4 = original color 4

Color 5 = original color 5

File: C:\Roses Bottom #2.PES

Color 1 = original color 1

Color 2 = original color 2

Color 3 = original color 3

Happy Embroidering!”

As you can see, the table is easy to follow. Since this is a text file, you can also edit it (double-click to launch Notepad), print it, etc. It is a good idea to add any real thread numbers or names if you have them. Often, the digitizer of a design will supply a real-color thread list for this purpose.

We cannot stress enough the fact that the order of embroidering the files is important.

The files will overlap each other as they sew. If you embroider out-of-order you will get overlapping that is incorrect, and parts of your design will not be visible!

On hoops that have three positions, the regions are named for you: Top, Center and Bottom. On hoops that have more positions, the other positions are given numbers, starting at the top. Hence, you might have a hoop with: Top, Pos. 2, Center, Pos. 4 and Bottom. Columns have names like “Left”, “Right” or “C2”.

To get the best results, there are some things you should know.

First is that you should trim your jump stitches as you go, if your machine does not do it automatically. This is true in the course of normal embroidery, but somewhat necessary when embroidering a split design. When splitting a design, it is natural that the machine will have to go from place to place a little more frequently. This results in extra jump stitches. We have made every effort to minimize the amount of effort that it takes to split embroidery files, and apologize for any inconvenience this may cause, but please accept our assurance that your finished product will have a nicer appearance if you clean the jumps from the design.

If you are using an appliqué design, you will need to embroider each color in each region before moving on to the next color. This will ensure that the full appliqué can be applied without incorrect oversewing by the other colors.

There is a compensation control in the Hoop Properties window. This control is available on all hoops, even the factory-defined ones. Compensation is the amount that each region will overlap the neighboring regions. This is used to correct for the fact that fabric will shrink as it is embroidered. Additionally, an imperfectly hooped project will allow registration problems to occur. If you are not able to hoop your fabric, ‘Drum-tight’, then you may want to increase the compensation setting for your hoop.

Important: If you are increasing the size of a design, please don’t increase the size more than you will actually need for your hoop.

Note: There is a very important phrase in the computer industry: “Garbage in, garbage out.

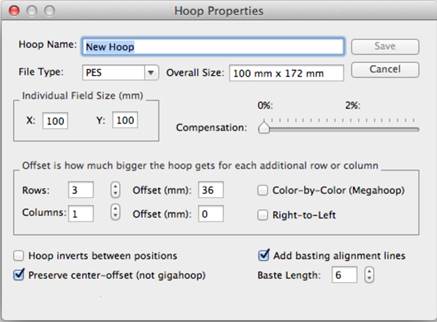

When you click the “New” or “Edit” button in the Hoops Available window, you will see this screen:

EXPLANATION OF FIELDS:

• The first field in this window is the ‘Hoop Name’. This is just what it sounds like. Type in whatever name you want.

• Next, choose the ‘File Type’ of the machine that this hoop works on. The list contains the file types that can be saved.

• The ‘Individual Field Size’ is the size (in mm) that your embroidery machine can create with a single hoop position. If you are unsure about this size, consult your dealer.

• The ‘Rows’ field specifies the number of vertical points at which the hoop can be attached to your machine. For most multi-position hoops, this number is three. For sliding hoops such as those made by Hoop-It-All, you will have to determine how many sections you want to embroider in. In so doing, however, keep in mind that there should be a good overlap between adjoining sections. Use the hoops we’ve provided as examples.

• The ‘Columns’ field specifies the number of points at which the hoop can be attached to your machine sideways. For most hoops, this number is one, but there are exceptions on the market. These are usually described as “Double-Wide”. You can also use the columns to indicate that you want to divide the design into horizontally-tiled segments.

• The ‘Separation’ fields specify the distance between the hoop positions. (For example, the distance from needle-center of the top position to the needle-center of the middle position.) This can be measured physically if you do not know: hoop a piece of paper and drop the needle through it, in all hoop positions, measuring the distance between the holes. Alternately, most manufacturers’ software will show a grid behind the hoop on the screen. You can count the grids (usually 1 grid = 10mm) between the region marks to get the separation. It is very important that you correctly assign the separation; otherwise the design will not be split accurately.

• The ‘Right-to-Left’ field is used for multi-column hoops (‘Double-Wide’). It indicates that the initial direction the program will split the design will be right-to-left, as opposed to the standard, left-to-right. The use of this depends on the machine and hoop. Some manufacturers have wide hoops that start by sewing the left side of the design upside-down, then you turn the hoop halfway around and embroider the other side (now the right side, and the design is right-side-up). Hence, the default, ‘Left-to-Right.

NOTE: You can tell if your separation figure is correct! The manufacturer of the hoop will definitely provide you with the number of positions used as well as the full size of the embroidering region of the hoop. As you adjust the separation, the field, “Overall Size” is calculated. If this matches the figure given to you by the manufacturer, you have correctly set your separation.

• ‘Compensation’ allows the final regions to be slightly increased in size. This forces the regions to overlap each other. This is useful because as the machine adds stitches, the fabric gathers slightly. It is entirely possible to have a gap between regions if no compensation were to be used. The amount of compensation required depends on several factors: The size of the hoop, the fabric being embroidered, the number of stitches, the quality of the stabilization, etc. We have chosen some settings for our factory hoops that have worked well in our design testing. Please embroider some test designs with the desired hoop before tackling a project. This will ensure that you have a reasonable setting for your compensation.

• ‘Color-by-Color’ denotes a different type of file splitting. As of this writing, only the Viking Mega Hoop™ allows for this type of design splitting, so as a general rule, never check this box. The Color-by-Color method is for use in machines that can sew each color in all of the hoop regions before going on to the next color. When the machine operates this way, it will stitch in its current region until it no longer can. It will then stop and ask the user to reposition the hoop, whereupon it will continue stitching. In the case of most designs, this will cause a lot of position switching as a color typically stitches objects out in a random fashion all over the design. The program will ‘sort’ the stitch objects to reduce the number of position-switches required.

• ‘Invert Alternate Column’ is used for ‘Double-Wide’ hoops that get turned upside-down for their second row.

• ‘Add basting alignment lines’ will provide a basted line of stitching to each output file. These lines of stitching will have their end and/or center points line up on the fabric when you go to stitch out the designs. If the lines do not line up, then adjust your hoop/fabric position until they do.

• ‘Baste Length’ sets the size of the alignment line stitching, in mm.

Once you have finished creating or editing your hoop, simply click, ‘Save’ to save it.

If it is a new hoop, it will appear in the Hoop Available window.

You can split the design using “Split Into Hoop” from the Utility menu. This will open a new design page with the split files so that you can preview them or do other work before saving.

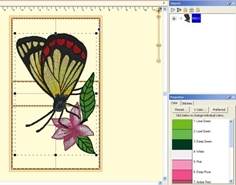

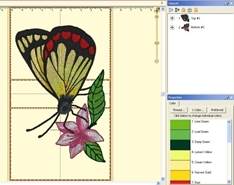

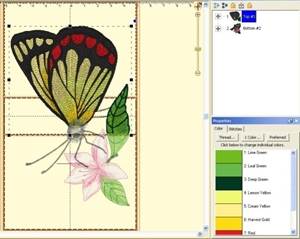

Left: A single design placed on a 100x172 hoop. Right: The design has been split.

In the example above, the 100 x 172 PES hoop was chosen, and the design was centered in it. Then the menu item, Utility->Split Into Hoop was chosen. This created a new design page, represented by a new tab. In that page there are two designs, one for the top hoop section, and one for the bottom. Using ghost mode, we show the designs separately:

Left: The top design is selected. Right: The bottom design is selected.

When you save this page, multiple stitch files will be created, as described in the next section, “Output Files.”