StitchArtist is a program designed to allow embroiderers to

create stitch designs from scratch using existing artwork or by ‘drawing with

stitches.’ It has been described as an object-based digitizer. You draw and

control the shapes, set the stitch type and properties, and StitchArtist

generates stitches for you. When you want to create stitches, that’s what it

does.

StitchArtist comes in levels that suit different skill level

embroiderers.

Note: Each topic in this manual may

have notes for different levels. This allows for continuity in the learning

process. As you progress, you can purchase additional levels whenever you are

ready.

Level 1 is designed for a hobby embroiderer who needs to be

able to create stitches without going into debt or spending much computer time.

Level 1 offers a limited set of stitch types and, more importantly, properties

for those stitches, so that the user can simply ‘create.’ Typical projects for

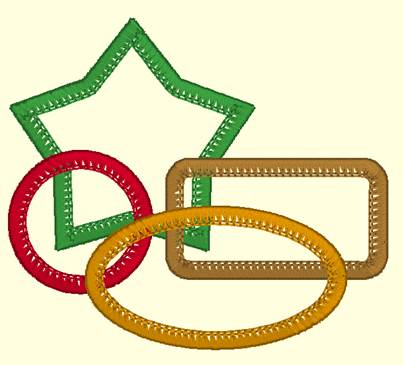

Level 1 are applique designs, running stitch designs and simple filled shapes,

backgrounds or unifying elements for design compositions etc. It is not designed

for logo work or publishing, unless you’re working with applique.

Level 2 includes Level 1 and is designed for basic skills

training for those who would like to create more sophisticated designs, as well

as a basic set of tools for logo creation. It will allow the user to learn a

wide cross-section of stitch types and properties, and have enough freedom to

create virtually anything.

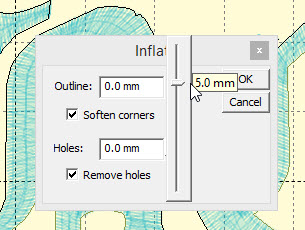

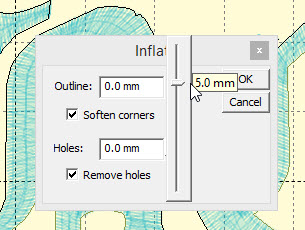

Level 3 includes Level 1 and Level 2 and is designed for

someone who either loves to create designs or works commercially in the

embroidery field. This level includes advanced items such as QuickStyles, adding

user-created motifs and designs, graphical operators such as Reconstruct,

Outline Stitches, Inflate, Cut, AND, Union and Break, extended Vector support

and more.

Note: Illustrations in this manual are shown with Level 3

enabled unless otherwise noted. Feature differences in other levels will be

discussed in the text.

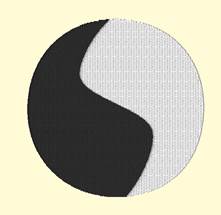

StitchArtist is not an attempt at fully automatic design

creation. It will not attempt to ‘convert an image’ into embroidery; It does not

contain photo-to-stitch for example. These are all reasonable tasks, but are not

the same as what StitchArtist is.

It is also not a ‘customizing’ or ‘editing’ program for the

manipulation of existing embroidery designs. You may load designs so that you

can add stitches to them, but they are not alterable in most ways.

Embroidery designs have been created with computer programs

since the late 1970’s. The hardware used by artists at the time came from the

CAD/CAM industry (Computer Aided Design/Manufacturing) and consisted of a CAD

“digitizing” board (like an architect desk) and a mouse-like ‘puck.’ As no one

thought to change the CAD term, the word “digitizing” has been with us in the

embroidery craft ever since. We prefer the term “Design Creation” though

for two reasons: 1: Because it really is more accurate. And 2: Because the

term “digitizing” carries negative connotations of difficult-to-learn software.

Therefore “Digitizing” and “Design Creation” are interchangeable in this manual;

however, our product is a change in the user interface, and is easier to use.

Just wait, you’ll see.

Design creation is a two-fold learning process. First, there

is the software. That is the set of buttons and sliders that make objects to be

stitched. That’s pretty easy to learn, especially for anyone who understands

drawing programs or even has general computer skills. Whereas digitizing

software in the past had been developed in its own little world, and the

graphics programs went their own ways, the two are now converging with similar

tools and operations in both. Do not be misled into thinking that embroidery and

graphics are at all similar though, as designers can get away with all kinds of

things in graphics that simply are not possible in embroidery. The level of

sophistication in an embroidery creation program is much higher than a graphics

program, generally speaking.

That brings us to the second and more difficult part of the

learning curve – the knowledge of embroidery itself. Embroidery involves thread

and fabric. Both are flexible, usually stretchy to some extent and operate

differently in different combinations. In graphics you can do things however you

want: In any order, at any place, or jump from point to point without regard.

And the result will always look the same. With embroidery all those assumptions

are false. You need to understand which stitches will go down first, and why

they go there, and you need to really think about where the machine is going to

go as it stitches the design. Generally, there are three areas of thought that

need to be part of your process when you create a design:

•

The material, thread and project combination. This dictates certain items

such as the amount of coverage you need, the maximum number of stitches within

an area that can be added to the fabric before it puckers, and how it will be

stabilized so as to mitigate somewhat the inherent limits of the fabric.

•

The path the machine will take as it creates the design. You don’t want

to leave thread trails all over, and you don’t want to have to cut those either.

Even if the machine does that for you, you still have to spend the time on that

process. And if a design always sews in a given direction, you wind up pushing

the fabric around so much that the later stitches won’t align or ‘register’ with

the earlier ones.

•

The types of stitches used. This is the topic that is easily

understood, but can take a lifetime to master. The basic stitches are pretty

obvious, but the quality of the output comes from clever usage and combinations

of elements.

This manual covers the usage of the program itself, and

attempts to interject some knowledge of the embroidery process as well. However,

we very much recommend the reader take educational programs on design creation

from others. There are a number of wonderful educators for digitizing in the

marketplace, and their fees are generally well worth the knowledge you will

gain. With respect to those instructors, please humbly accept that any

differences you find herein with regards to your teachings, are not intended to

be the ‘only way’ someone ought to do something, nor necessarily the ‘best’

approach, but perhaps is what we ourselves are comfortable teaching. We all have

our own styles, and those differ from time to time.

If you have never embroidered before, take some time to learn

the use of your machine and the basics of embroidery. Your local sewing machine

store will have classes that you can attend to help you get going. We must

assume for the purposes of this manual that you understand the ordinary hobby

aspects of embroidery – what a hoop is, what stabilizer is, what a ‘design’ is

etc. Hopefully you have at least stitched something successfully.

You do not have to be an artist. Really -- let’s say it again

--you do not have to be an artist.

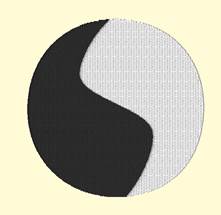

The reason is that embroidery creation is more of a

‘color-by-numbers’ process. You may be an artist, and that’s great. You can even

create your art within the program. However, the process of laying stitches on

top of your art or image is a mechanical, methodical and logical process,

provided that the art is suitable for embroidery. And there too is a reason why

we ask that you have at least done embroidery – it will provide you some insight

as to what’s possible with embroidery, and what simply isn’t. Naturally an

artist can alter a complex image to be more suitable for embroidery, and a

person with some experience creating designs may be able to do that intuitively

as they work. It all comes from the learning process and involves much trial and

error along the way. You won’t learn to paint overnight, nor learn to play

Chopin the first time you sit at a piano, so please don’t expect to be creating

complex designs well the first time either. But with a bit of persistence,

creating designs is a much faster and easier learning curve than those other

endeavors, and you can begin with simple things and start sewing in practically

no time.

Reminder

about Levels: Illustrations in this manual are shown with Level 3 enabled

unless otherwise noted. Feature differences in other levels will be discussed in

the text. Some sections have information pertaining to multiple levels. We have

indicated the minimum level for which the text is relevant. Where practical, we

have added higher-level information toward the ends of sections.

The

interface in StitchArtist is different in some respects than programs that have

come before, especially digitizing software. We’ll define all these terms as we

go, but if you’re familiar with them already there are some things you should

know now…

The

interface in StitchArtist is different in some respects than programs that have

come before, especially digitizing software. We’ll define all these terms as we

go, but if you’re familiar with them already there are some things you should

know now…

When creating embroidery, you normally will be doing several

types of tasks:

1.

Loading artwork as the basis for the design

2.

Creating stitch-generating “objects.”

3.

Editing the “shapes” or “outlines” of those objects.

4.

Editing the “properties” for those objects.

5.

Moving objects around on the design page.

6.

Sequencing objects for sewing order.

7.

Adjusting the “entry and exit points” for sewing objects.

8.

Colorizing objects.

In StitchArtist these different types of operations do not

require any program ‘modes’. Generally speaking, there are only two modes that

you’ll run into during design creation: The normal ‘Selection’ mode when the

program starts, and the ‘Creation’ mode that you’ll use while creating the

designs.

You will not need a separate tool to reshape the outline of

designs, nor need to switch modes to size or move objects. All the tools for

design creation are accessed from either the ‘Create’ menu or the ‘Create’ Tool

Pane, which is shown using the ‘Create’ button on the main toolbar.

All selected objects have their properties adjustable at all

times, and the properties can be set on any number of selected objects

simultaneously, causing immediate generation of the selected objects.

There are also virtually no “Apply” buttons or ‘Enter’-key

requirements – stitch generation is automatic and immediate.

There are a number of features in the platform that are

consistent across the products including the Navigation HUD (a compass rose in

the top, right corner of the Main Window), the Zoom Slider, the Edit Menu, Zoom

keys, etc. Please review these areas in the program help so that you’ll know the

basic navigation of the program.

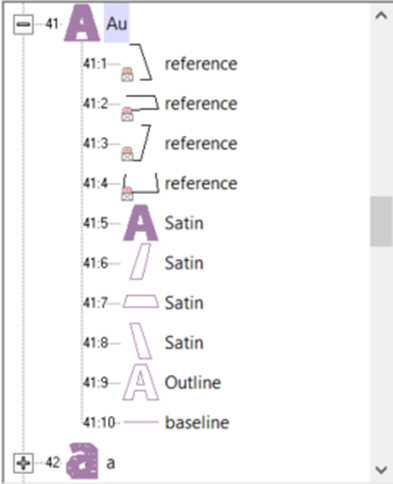

Design Pages, Designs and Objects

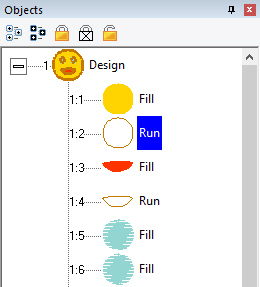

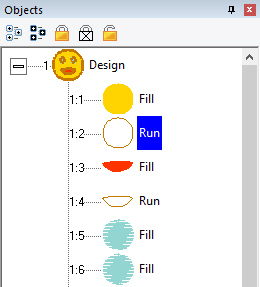

Objects are usually shapes that have stitch types and

properties associated with them. The object may for instance be a Run, or a

Satin Column or perhaps a Fill.

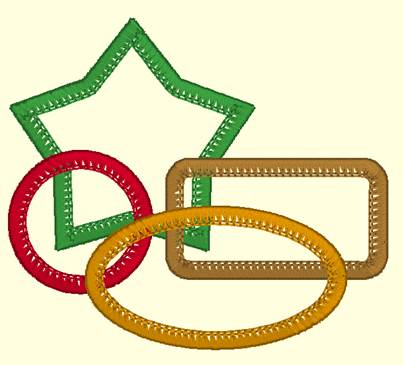

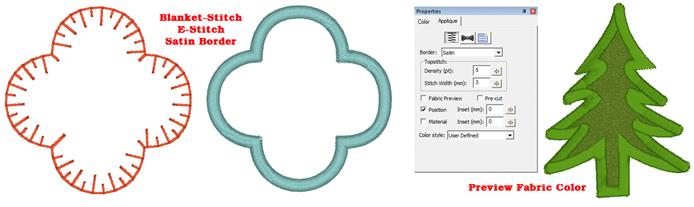

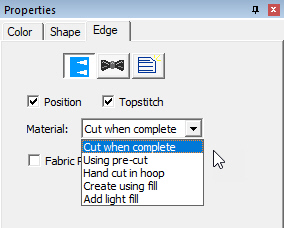

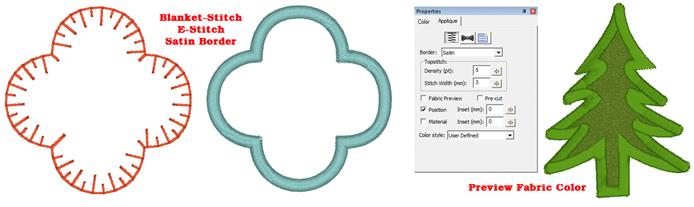

Objects can contain lots of information: Outlines, holes,

inclinations, breaks, images, stitches and colors. Thus, a single object could

contain an applique – the shape of the applique, a picture you want to print

cropped in the outline, the stitches that are generated to sew the applique and

the colors for the position, material and topstitch sewing, and even more. We’ll

discuss all that separately, so please keep reading.

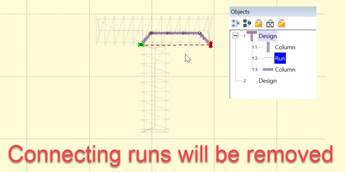

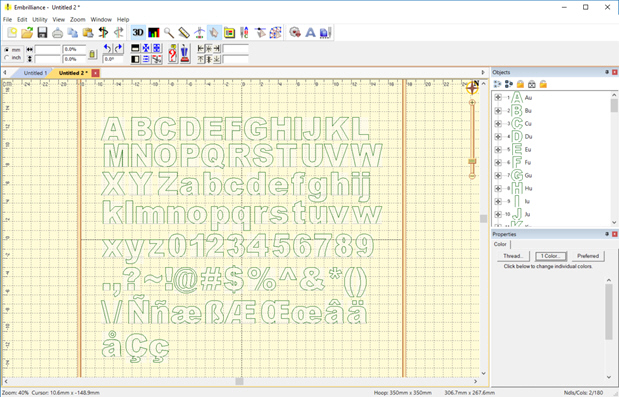

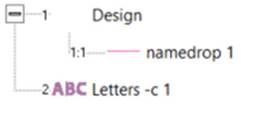

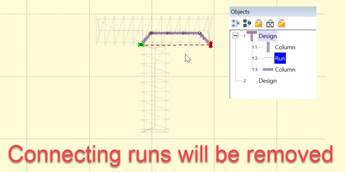

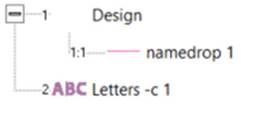

Designs are groups of objects that are collected together.

This might be an individual design that you want to sell, or a smaller piece

that you’ll reuse as an element in other designs. Designs let the user work

within a section of an overall composition without being encumbered by the

whole. This is similar, but not equivalent to, a term used in some graphics

programs as a “layer.”

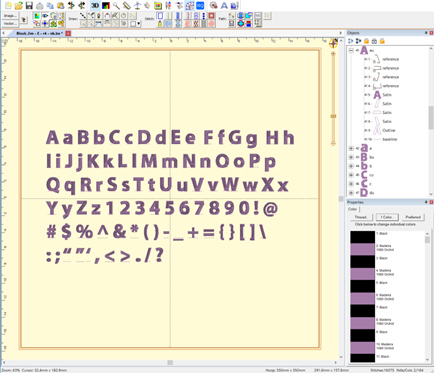

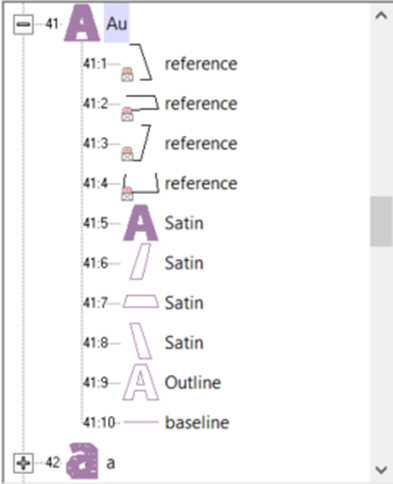

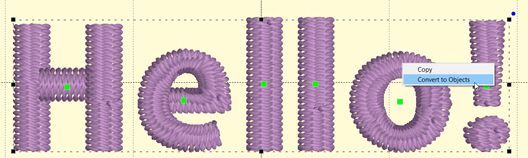

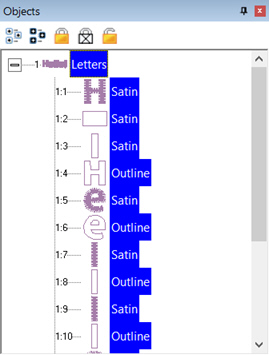

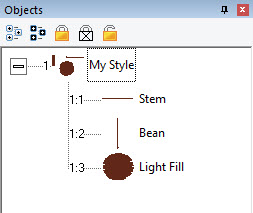

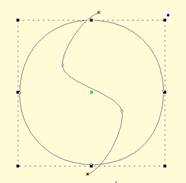

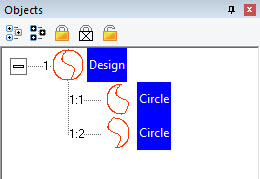

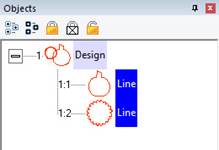

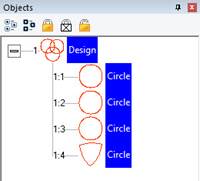

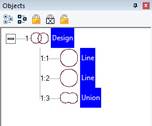

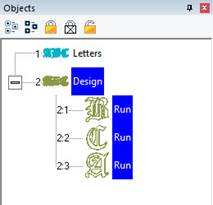

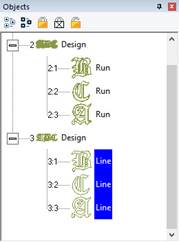

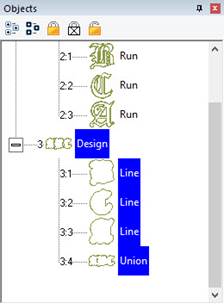

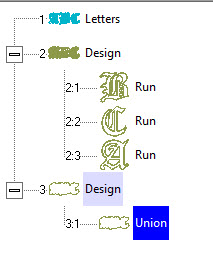

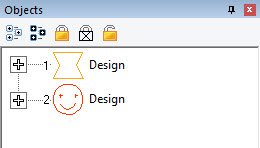

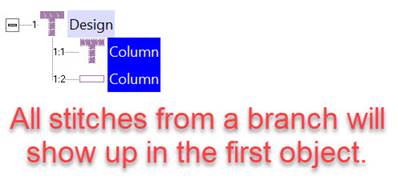

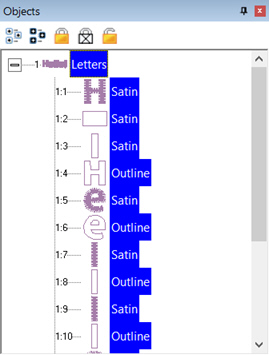

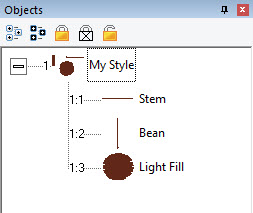

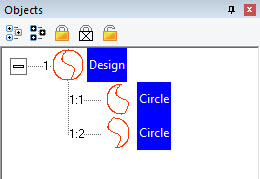

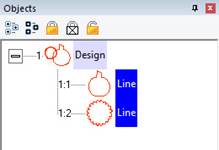

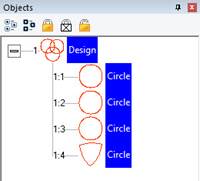

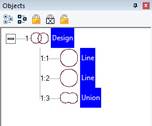

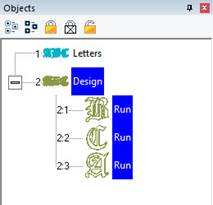

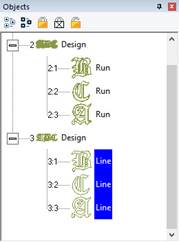

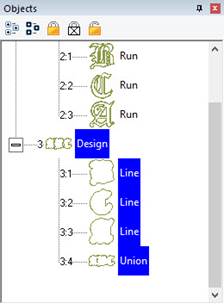

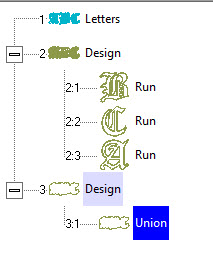

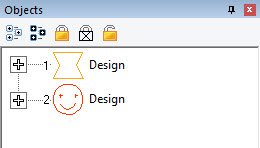

When observing the relationships between designs and objects,

see that the Object View, normally docked on the right of the program screen,

has at its ‘root’ level the designs, and when you expand a design, you’ll see

the individual objects that compose that design. If you select a design, by

clicking on it in the Object View, you will be selecting all the objects

contained in that design as well. If you select all the objects in a design,

selection of the design itself is optional. This is useful for copy/paste

operations.

When creating new objects, you have the ability to choose

where they go – into which design, and even where in that design they are

created. We’ll talk more about that in the ‘Creating Objects’ section.

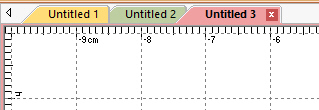

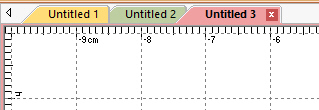

The top level of the program uses what is called a Design

Page, which is related to a document or file. The Design Page is stored as a .BE

file on your computer, and can contain any number of designs, each composed of

any number of objects. You can have as many open Design Pages (or documents) as

you like, and each is represented by a tab at the top of the main view.

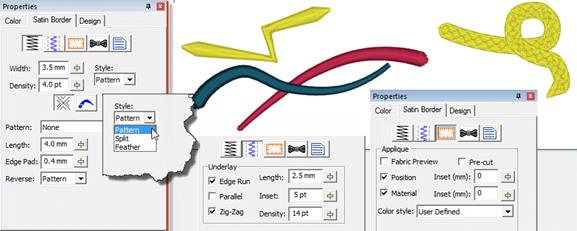

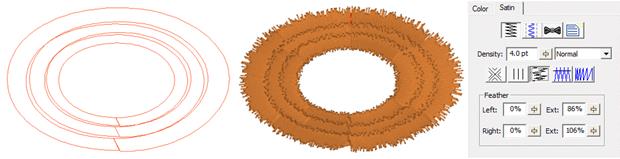

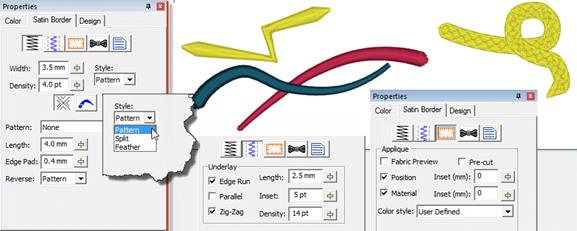

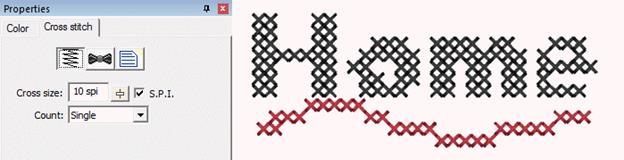

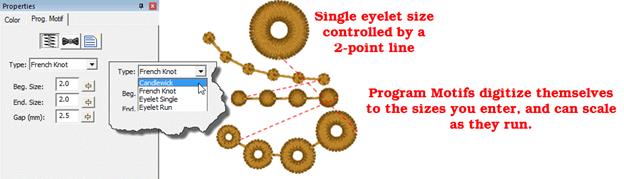

Properties

The interface has a Property Page, usually visible on the

lower right part of the program window. The size of the Property Page can be

adjusted using the splitter bar that lies at the bottom of the Object

View. You can also drag the splitter bar that lies on the right of the

Main View if desired. For general interface adjustments, please review the user

interface section of the program help.

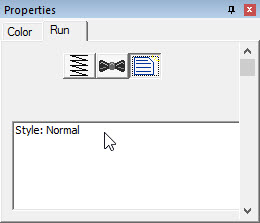

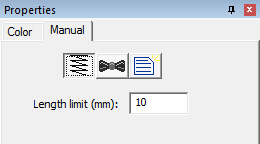

When you select objects, their properties are shown as tabs in

the Property View. If you have more than one object of a given type, the

properties of the first selected object of that type are shown.

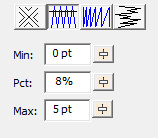

The controls for the properties mostly exist in five

forms:

1.

A set of buttons that let you choose which properties you are adjusting.

2.

A drop-list that lets you select from a set up options.

3.

An editable text field that lets you adjust a value.

4.

A pop-up slider that lets you set an adjacent text field by dragging its

value.

5.

A check box that lets you turn a property on or off.

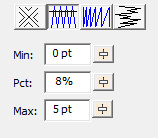

If you adjust a property, all the selected objects of that

type will have that specific, and only that one, property adjusted. Having

adjusted the property, the stitches will generate automatically. You should see

the change in the stitches of the object immediately.

Color is a property of an object. Objects have one color each,

except for appliques, which by definition need to stop the machine. When

exporting stitches, objects of the same color that follow each other will not

cause the embroidery machine to stop unless there are applique steps

involved.

When no objects are selected, all of the colors for the page

are visible and changeable. To change a color, simply click on it in the

list.

The Color Properties window.

Thread line selected

Palette selected

Design creators often need to utilize a palette of given

colors. Sometimes these represent a customer’s job requirements, and other times

it is merely a matter of needle assignment for the embroidery machine. You can

create palettes at any time using the menu Utility->Threads… And you can

choose to use any palette as you adjust the color properties.

You can also create a palette on the fly while creating your

design. If you wish to switch to an already-used color on the current page,

select the ‘Palettes’ button in the color window and you will see in the list,

“*Current Page.”

The Tool Pane

The tool

pane is located below the main toolbar. When you click the toolbar button to

create stitches, you’ll see this tool pane, which is divided into sections.

The tool

pane is located below the main toolbar. When you click the toolbar button to

create stitches, you’ll see this tool pane, which is divided into sections.

The first section is used to bring existing images or artwork

into the program. You can load a raster image (Bitmap, Jpeg) or a Vector image

(Metafile, Adobe Illustrator) or even use a TrueType font as artwork for your

creation.

The next section contains view and mode options. You can hide

the background images or the stitches while you are creating your designs. You

can also re-sequence the objects in a mode that lets you click on them one after

the other on the Main View.

The drawing tools are next. These let you create shapes, open

and close outlines, add inclination and carving lines, etc.

The Stitches section is used to apply stitch types to selected

objects.

The Paths section is used by illustrators to convert images

into useable embroidery shapes.

When using tools such as the Magic Wand, another section

becomes visible as needed to allow for adjustments to the current

process.

Sometimes you want to pan the screen – in other words, move it

around – while not changing your zoom, or using the scroll bars. The easy way to

do this is with the spacebar key. Hold the spacebar down, your mouse cursor will

change to an image of a hand, and then drag the screen with your mouse.

While drawing shapes or dragging during edits, it is quite

common that you will need to move to part of the image that’s not on the screen.

Rather than use the scroll bars, which you can, you can also move the mouse to

the edge of the main window. When you get within a few pixels of the edge, the

view will scroll for you in the direction of the edge your mouse is over. When

not dragging, the screen will not scroll automatically.

Sometimes you want a reference line that is not on the main

grid. Place your mouse inside the area of either ruler – horizontal or vertical

at the top or right edge of the Main View. Then, drag, using the left mouse

button and you will then be setting a guide line. You can drag these guide lines

wherever you like, and if you drag one back to the ruler area from which it

came, it will be removed from the page.

Sometimes

the view of the artwork makes it hard to see what stitches you have created. You

can quickly toggle the images on and off using the Image Toggle button on the

tool pane or using the ‘b’ key.

Sometimes

the view of the artwork makes it hard to see what stitches you have created. You

can quickly toggle the images on and off using the Image Toggle button on the

tool pane or using the ‘b’ key.

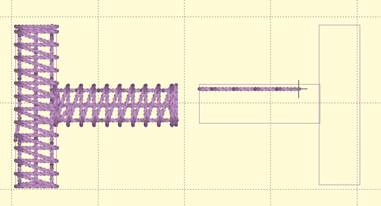

The stitches are usually kept in view so that you can see what

they are doing. However, sometimes you want to see only the outlines, and hide

the stitches. This is done with the ‘Stitch View’ toggle button on the tool pane

or with the ‘n’ key. This is helpful especially when editing.

Note:

Stitches

are not in view while drawing or scrolling.

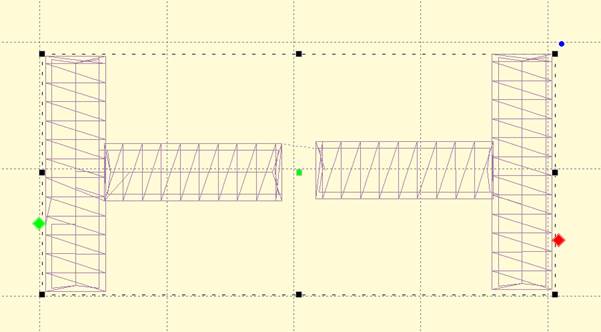

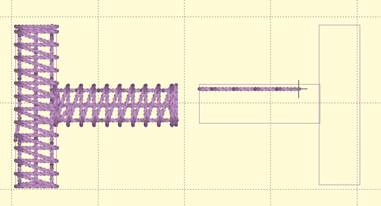

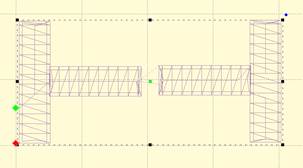

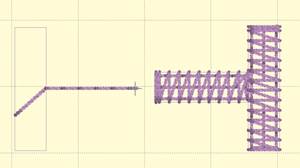

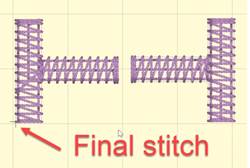

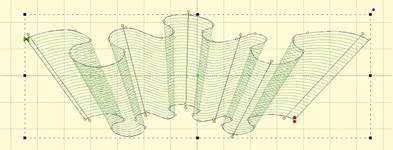

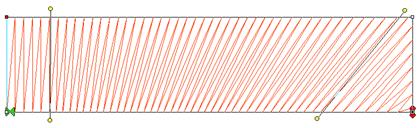

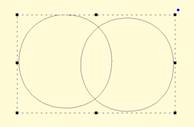

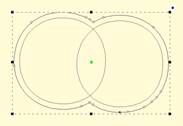

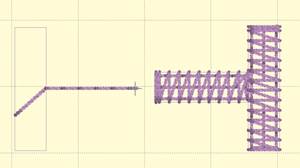

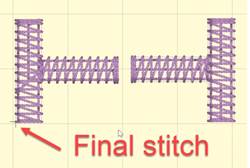

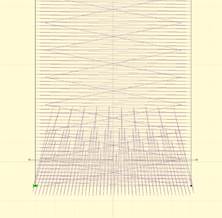

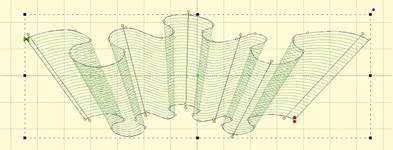

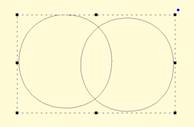

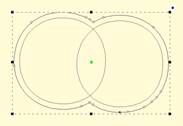

The

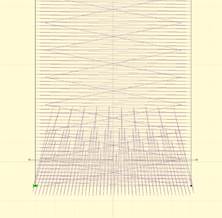

Continuous View is used to see how items will connect when embroidered in a

continuous hoop, or as a repeated pattern. It creates a set of duplicate images

that let you see how your design will connect or interact with an identical

copy. The image is not an actual design – it is just an image for

reference.

The

Continuous View is used to see how items will connect when embroidered in a

continuous hoop, or as a repeated pattern. It creates a set of duplicate images

that let you see how your design will connect or interact with an identical

copy. The image is not an actual design – it is just an image for

reference.

The offset setting allows you to

inset a repeated element, instead of the default, 0, which aligns the image of

the copy with the outer edge of the design.

Some digitizers advocate getting used to a particular scale or

scales while you are creating a design. This allows you to learn what a useful

distance in the real world will look like on-screen. The Embrilliance platform

has a Preference that lets you calibrate the display to a Real Scale (See the

program help on User Interface for details). Once you have done that for your

computer/monitor setup, it does not need to be done again.

To get to a particular ‘zoom’ level, use the number keys. ‘1’

is a 1:1 ratio of the size of things on-screen to the real world. 3:1 and 6:1

are popular as well. If you use the number key ‘0’ you will be zoomed to your

hoop.

Using a consistent set of scales is useful. Once you become

well used to seeing design work at those scales, you’ll be able to know what the

stitches will look like without having to sew them out. If you are zoomed too

far in, you will likely be creating more detail than the design will need which

slows the design creation process and can even negatively impact the sew-ability

of the design.

If you are editing a design, feel free to use the zoom slider

or other keys such as ‘A’ (All), ‘S’ (Selected) to work at a comfortable level.

Generally speaking, unless an object outline is very large, you should be able

to see the whole object on your screen while editing. Zooming in extra close can

be useful to make the nodes line-up perfectly, but that is not necessary for a

great design.

Note: If you have any objects

selected, using the “s” key is a quick way to center the Main View on them for

editing.

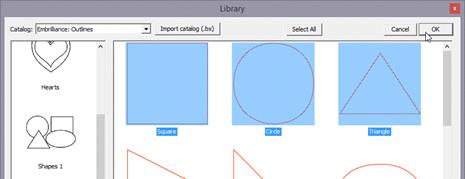

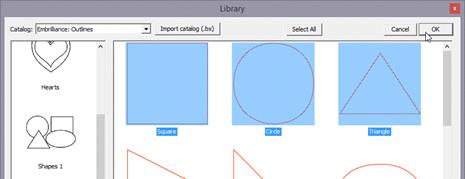

The

Library button on the main toolbar will bring in design collections that have

been published in the platform. There are several collections included which

allow you to use them in your own work – saving you time in drawing these

shapes. When bringing in a library shape, the program uses the current page’s

view center and zoom level to determine where it will come in. Once it has been

brought in, you can size and place it as needed, even edit its outline, as if

you had drawn it yourself.

The

Library button on the main toolbar will bring in design collections that have

been published in the platform. There are several collections included which

allow you to use them in your own work – saving you time in drawing these

shapes. When bringing in a library shape, the program uses the current page’s

view center and zoom level to determine where it will come in. Once it has been

brought in, you can size and place it as needed, even edit its outline, as if

you had drawn it yourself.

The Library has been extended to include hundreds of outlines

that you can use with StitchArtist to make your own designs. They are even

royalty-free!

Working with Designs

Designs and objects will create themselves as you begin

drawing and as a result of copy/paste operations. But there are some options you

should be aware of.

Each design page, which is represented by a working file (.BE)

is selected using the tabs at the top of the main window. Each page can contain

any number of designs. Sometimes it is useful to break up your work into

discreet areas that can be managed as a unit. Designs are the mechanism for

this. For example, suppose you make a nice rose. Now you want a bouquet. You

could make the rose as a single design, and then place it in multiple positions

and sizes to complete your image.

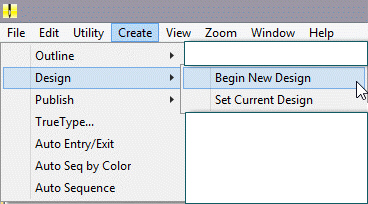

If you have no designs on the page, one will be created for

you when you either bring in artwork or begin to draw. However, if you wish to

switch to a new design to begin drawing a separate piece, you use the menu

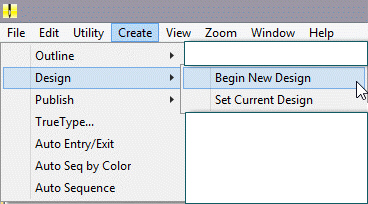

Create->Design->Begin New Design.

If you are working back and forth between multiple designs,

when you draw new objects, you will need to decide where they go. To do this you

have options:

1.

Select the design in the Object View, and then use the menu

Create->Design->Set Current Design.

2.

Select an object in whichever design you wish to work, and begin drawing. Your

new object will appear in the sequence following the object that was

selected.

In computer graphics there are two basic ways to create an

image and those are called “bitmap” and “vector.”

There are

buttons to allow you to bring in artwork from files. To use an image file such

as a .bmp or .jpeg as a backdrop for your design, click the “Image…” button.

There are

buttons to allow you to bring in artwork from files. To use an image file such

as a .bmp or .jpeg as a backdrop for your design, click the “Image…” button.

Alternately, you can drag and drop image

files, filenames, or simply have copied images from a web browser or other

program, then paste onto the design page.

Once you have selected an image, the program will

automatically begin a design for you (if you haven’t already), and place that

image as a new object in the design. The image is selected and can be scaled or

rotated, squished, etc. The images used for backgrounds generally are preferred

to be semi-transparent, and that is also set for you. You can do whatever you

like with the image at this point to help you begin creating stitch objects on

top of it.

Once you begin making other objects, the image itself will

lock into place. This means you will not be able to accidentally select or move

it while you are creating your design. You can still edit it by selecting it in

the Object View. There, you can even unlock it. Generally, once a stitch object

has been placed over an image, you don’t want it moving around.

Note:

The Image button works for

pixel-based images such as photos and scans. Files created using vectors are not

pixel-based images, and do not load using this function. See the section on

Vectors for information about loading those.

Bitmaps are also known as “raster” images, which might be more

technically correct though the terms today are used interchangeably. Bitmap

images are composed of different colored dots. Images such as photographs fit

into this category. Bitmap representations of art are the preferred type

to create stitches from; they come in as background images over which you will

create stitch objects.

When using a bitmap image, there is the issue of “resolution”

which refers to how many dots called “pixels” are being used. The more pixels,

the better the clarity of the image and fewer pixels make for an image that has

little stair-steps in it when you zoom in. One might think that more pixels are

better. However, the program has to do a lot of work while you are drawing your

design and an image with a lot of pixels makes it take that much longer to do

each step while you are working. So, it makes sense to use an image that is not

super-duper-hi-resolution.

When deciding what resolution, you want to use, or how many

pixels should be in the image, it is worth considering how that will match up to

the embroidery design itself. In an embroidery design the most common density of

a stitch is about 0.4mm or 4 stitch points. This equates to a resolution of 64

DPI (Dots Per Inch) and that means that a typical 4” (100mm) square design would

only need an image of 250 pixels on each edge. The normal smartphone will give

you thousands of pixels on an edge, so any photo today probably has more than

enough resolution for what you need.

We recommend, for simplicity, that you keep your image to

around 1000 pixels on either edge. You can go for more if you’re making a super

large design, naturally, but otherwise this is a good number. A lot of graphics

that exist on the internet are 1024x768 or 800x600 because these are common web

sizes. And those images have plenty of resolution for you to create embroidery.

If you are making a 14” design, you might want to bump that to 1500-2000 pixels

on the widest edge. But remember more is not always better.

Vectors (Level 2, 3)

Vector

files are artwork themselves. These files are brought in as objects. The user

must realize that graphics files contain objects with outline weights

(thickness) and all sorts of color properties that are inapplicable to an

embroidery design. As such, when importing vectors, the outline and its color

are all that are brought in. For some designs, this saves the user the work of

having to re-draw the image.

Vector

files are artwork themselves. These files are brought in as objects. The user

must realize that graphics files contain objects with outline weights

(thickness) and all sorts of color properties that are inapplicable to an

embroidery design. As such, when importing vectors, the outline and its color

are all that are brought in. For some designs, this saves the user the work of

having to re-draw the image.

In addition to the Vector button, you can drag and drop .svg

files or filenames then paste onto the design page. In the case of copying from

a drawing program, many will simply put a bitmap representation on the

clipboard. This is often acceptable, as most digitizers redraw over the image

anyway.

Vector images are outlines filled with color – think of a

company logo, cartoon, comic or coloring book.

As vector images already have outlines in them, and embroidery

objects have outlines too, it might seem reasonable that starting with a

vector-based image is better for this purpose. You would have little to draw

because the art is already there for you. Simply set the stitch properties and

you’re done, right? Well, you can, and we do import them for that purpose,

but…

…In actuality that is rarely the case.

Vector artists can do things with their objects, such as

‘overlapping,’ which makes embroidery of the outline completely impossible.

Also, the shapes can be directly adjacent, which will leave gaps in embroidery.

And vector artists jump from color to color and back again very casually. You

don’t want to attempt this with embroidery. So, while the allure of using vector

files is there, it actually can take more work to make a vector-based image work

for you than simply creating objects over top of a bitmap image.

Another common problem using vector-based images is that of

the original source. There are a lot of clipart companies in the world, and they

offer their product in a variety of file formats. When an artist submits an

image that was created as a bitmap, the company then uses a program to

‘auto-trace’ the outlines in the image so that you, the customer, can get your

‘vector’ version of it as an EMF or WMF or AI file, etc. Those files are almost

universally the worst thing to use for the reason that they contain as many as

one hundred times the number of outline nodes as needed, and they are often

‘line’ nodes, which means the stitches that will be generated will have to stop

at each node.

Given these inherent difficulties, Level 3 has added features

that let you overcome these problems.

However, for all these reasons we suggest you always use a

bitmap picture - .bmp, .jpeg, etc. That is unless you yourself are the artist or

whoever is creating the vector files as the original format and have done so

with embroidery design in mind.

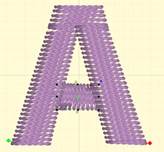

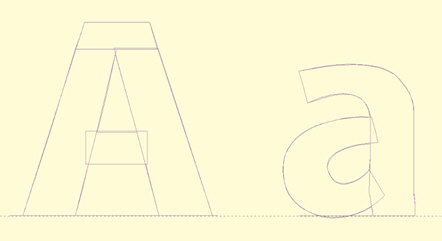

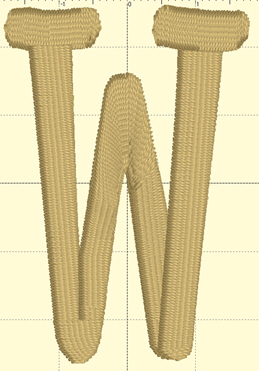

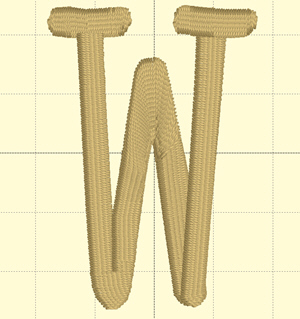

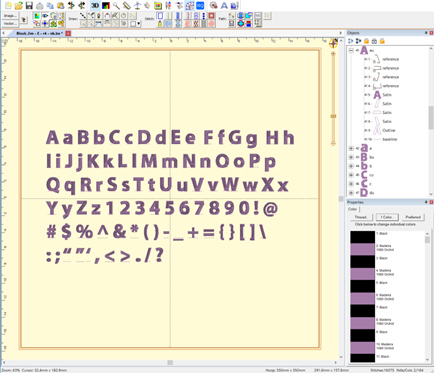

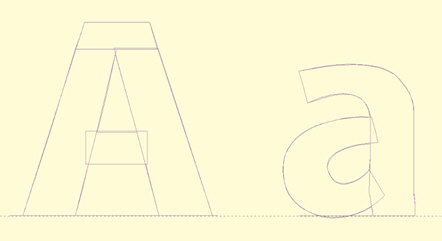

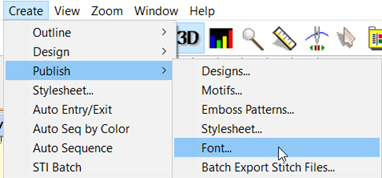

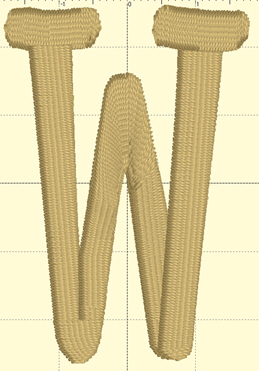

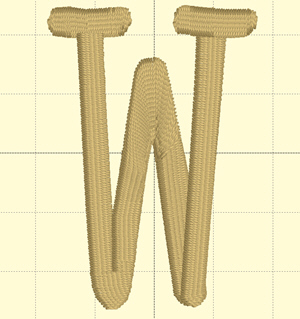

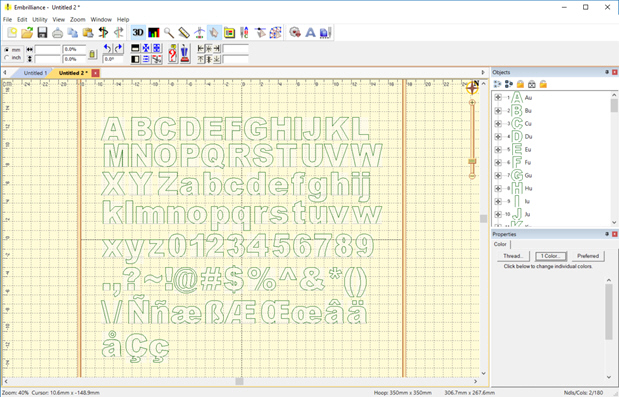

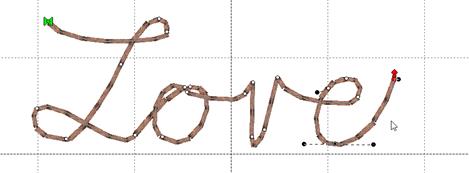

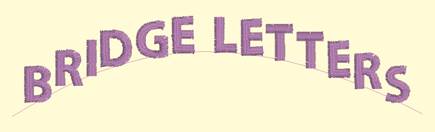

TrueType

fonts exist as single-color outlines in your computer. As many logos began life

as a TrueType font, you may want to use one as the basis for your design. There

are many free-to-use fonts available on the internet, although some require

payment if you use them. Check the font’s license to be sure, especially in

commercial circumstances. For this purpose, let’s assume you have either

permission or freely licensed fonts.

TrueType

fonts exist as single-color outlines in your computer. As many logos began life

as a TrueType font, you may want to use one as the basis for your design. There

are many free-to-use fonts available on the internet, although some require

payment if you use them. Check the font’s license to be sure, especially in

commercial circumstances. For this purpose, let’s assume you have either

permission or freely licensed fonts.

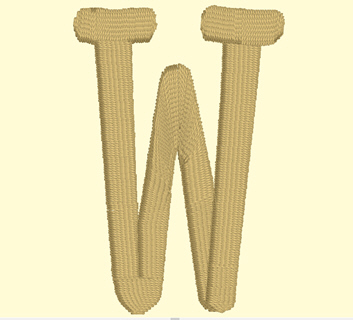

When you select text in a given font, the computer provides

that in outline form. Each outline is given as an object. For example, the

lower-case letter ‘i’ will usually have two objects; one for the dot and one for

the stroke. You can use these outlines as stitch types anyway you want. You can

make them outline designs by applying a run, or you could use the art for satin

stitches. You could even make them huge and set them to a fill, cross stitch or

applique. It’s just a piece of art as if you had drawn it yourself.

You may use the drawing tools in the program to create your

own art. There are enough tools there to do it, however, graphics packages will

offer more flexibility in terms of things like pen nibs and gradient colors, but

those are very different in embroidery when compared to graphics. Therefore, the

drawing tools in this program are geared toward stitch generation – you are

literally drawing with stitch-generating shapes, making you a Stitch

Artist.

As we explore the process of design creation, we need to get

some terminology out of the way. If a word stumps you while reading halfway down

a page, your brain will get stuck there and not retain anything else you’ve

read. So, let’s do some vocabulary, and at the same time, learn a few

things.

Objects are the building blocks of the design. There are

different types of objects, and their order or “sequence” is the order in which

the embroidery machine will sew them. Let’s look closer at what these really

are.

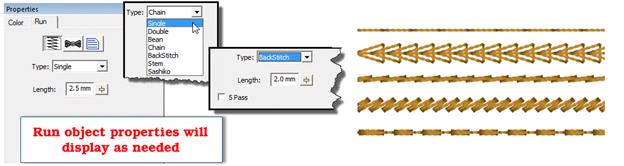

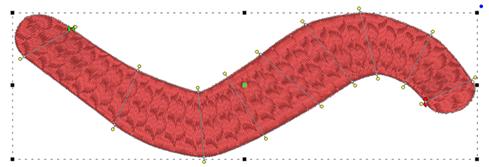

Objects contain outlines, colors and stitch properties. As

such we usually refer to the object by its stitch type, for example we may say

it is a “Run object” or simply a “Run.”

When you have selected an

object, you may want to change its stitch type. You may at any time change any

object from any stitch type to any other.

Some stitch types make use of the shape of the outline itself

– for instance, the shape of a Run is where the run will be placed – along the

outline. In contrast, a Fill would place stitches to cover the inside of the

shape. When a stitch type is used that fills a shape, the outline will need to

be “closed” and this happens automatically.

Objects have one stitch type. In StitchArtist, you are able to

apply any stitch type on any object. Thus, you could copy and paste an object

and change its stitch type, thus having a ‘Fill’ and a ‘Satin Border’ around

it. This allows you to adjust the outlines for each: In the real world of

stitches on fabric, shape adjustment of the outline will need to happen in all

but the most simplistic of designs.

When loading artwork for use as a backdrop for stitches, you

may load as many images as you want. Each will be added to its own object.

Ordinarily the first thing you would do when creating a design is to load the

artwork, position it on the design page, perhaps select a destination hoop size,

and then resize the image to that size. You can also rotate, stretch and mirror

the image as needed. The image will display with a default transparency that can

be adjusted using the “Bitmap” property page for the image.

Once you begin creating stitch objects on top of that image,

the image will “lock” automatically in place. This is the same as if you lock it

using the Object View toolbar buttons. A locked object means that it cannot be

selected by clicking on it in the main view, if it isn’t already selected. Any

locked object can be selected using the Object View. So, it is possible to move

or alter the transparency of the image even after you have begun to add

stitches, if you care to do so.

The platform is designed for the greatest flexibility in

design creation. This is to suit amateurs and experienced users alike, but that

flexibility requires some minimal explanation before you set off.

This is a chicken or the egg question. Any object may have its

stitch type set to anything. And that can happen during drawing, or after

drawing. What this means is that you can draw an outline, and then assign it a

stitch type. Or you can click a stitch type and then click a drawing mode to

begin. There is a catch with this order of operation though – If an object is

currently selected, and you click a stitch type, that selected object now

becomes the new stitch type.

To clarify, if you want to begin a new object by setting its

stitch type and then setting the input mode for drawing, make sure you don’t

have anything selected first. Click on the design page background to have no

objects selected.

If you prefer, you can select an input type, for example Point

input mode, then select the type of object it will be, for instance a Fill. When

you complete the outline, and the stitch type is set for Fill, the program knows

that you will also want to draw an inclination line to set the angle, so it will

automatically put you into that mode as soon as the outline is complete.

Some of you will prefer first to make your artwork as ‘Line’

objects with no stitches present, and then later set the stitch types. This is

perfectly acceptable. Simply begin drawing. If there is an object selected, the

new object type will switch to ‘Line’.

Often you will create a series of objects that are all the

same stitch type, for example: Run, Run, Run. In this case, after your first

object, make sure to click off it so that it is not selected. When you start

drawing the object type will be picked up from the previous object. Alternately

type ‘q’ to begin drawing an object using the input method and stitch type of

the last-drawn object.

The creation of objects is also likely to cover one or two

object types, repeated, one after the other. For example: Run, Satin, Run,

Satin, etc. Or, another example: Run, Double, Run, Double.

For this circumstance, you can quickly begin creation of an

object with two hotkeys: ‘q’ and ‘w’. These let you begin creating an object

using the exact method of the last object (‘q’), or the one prior to it (‘w’).

These hotkeys will not only select the object stitch type, but also the input

mode as well – you can begin drawing immediately. For more keyboard shortcut

information, please see the Keyboard Shortcut section.

Normally when you begin to draw a new object, it will be

placed at the end of the current design. If you wish it to be created in a

specific place, select the object that will sew before the object you are about

to draw, and then begin drawing your object. This is useful if you wish to go

back through your design and create connective runs between segments, or if you

simply forgot a piece.

Often you will have a lot of objects, and sometimes you’ll

want to find a selected object in the Object View quickly. Select it in the Main

view by clicking on it, and then use the context menu option, ‘Reveal in Object

View’. This will work only for the first selected object, if multiple objects

are selected. The Object View will scroll to position and expand the design

containing the object.

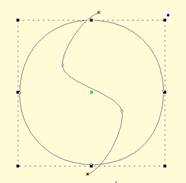

Drawing is the main bit of work used to create a design. This

section will let you know about various drawing methods.

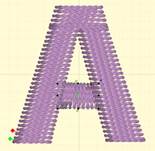

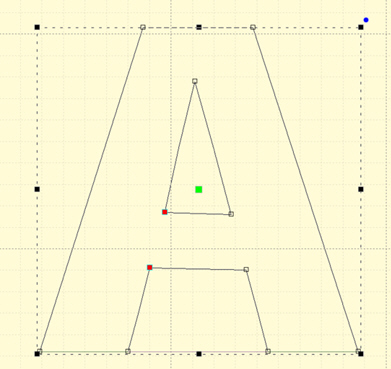

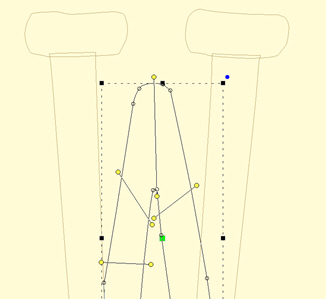

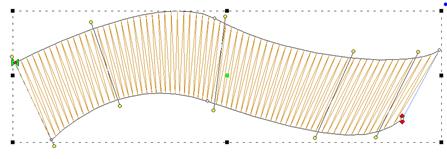

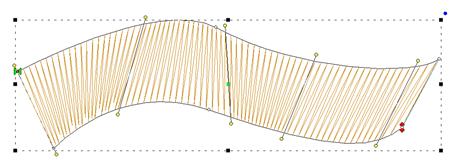

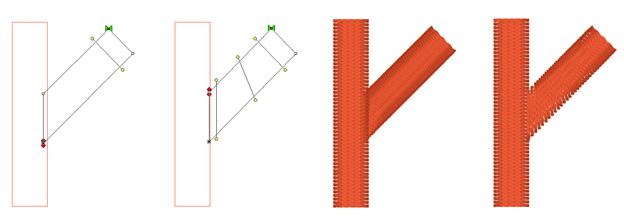

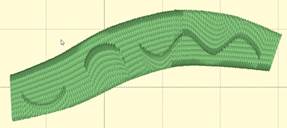

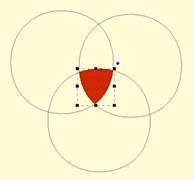

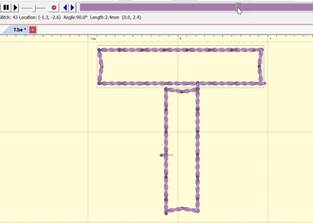

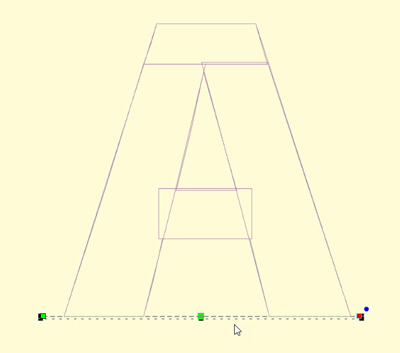

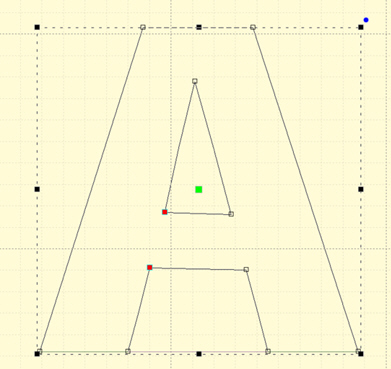

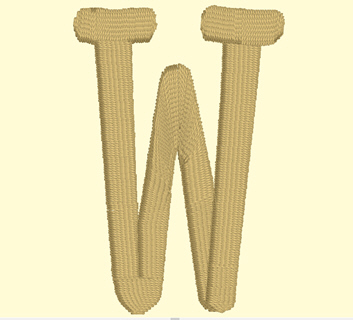

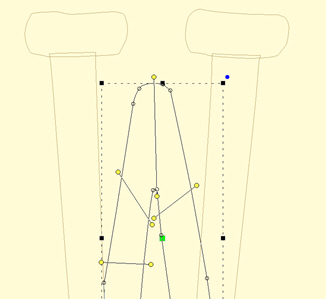

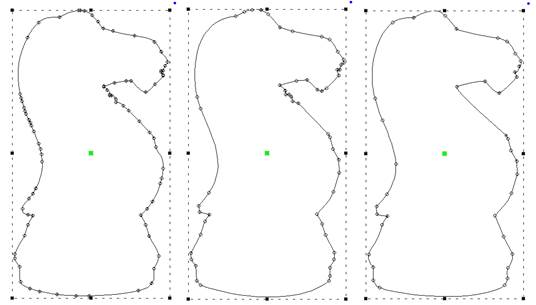

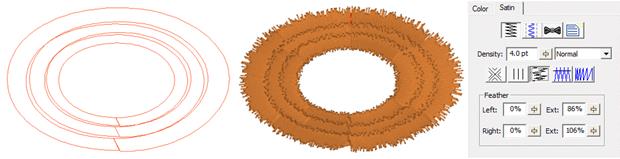

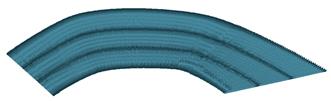

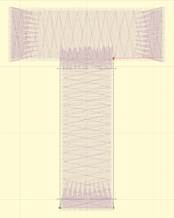

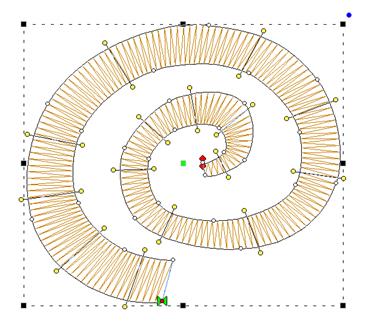

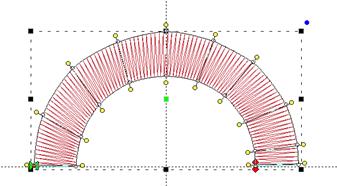

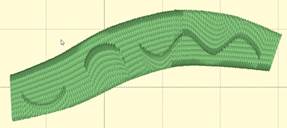

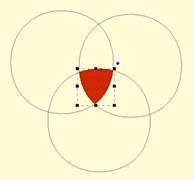

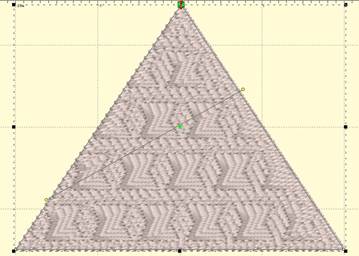

(Level 3 shown)

(Level 3 shown)

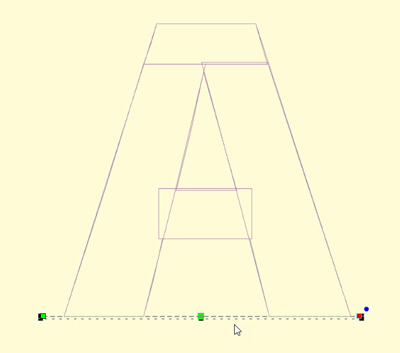

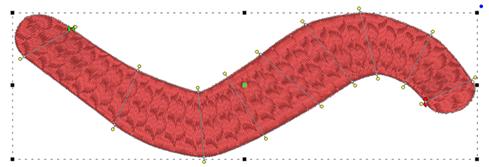

Objects are usually shapes called “outlines”. The outlines are

created by you, the user, drawing on top of a piece of artwork, importing a

piece of artwork called a “vector file” or with the assistance of a Magic Wand

(if you prefer not to create the shape yourself). An object’s outline may also

contain one or more “holes,” also interchangeably called “voids.”

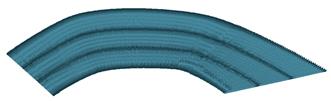

Objects will usually contain stitching of a certain kind, for

instance a satin-stitched column.

The outlines are shaped using points on the shape called

“nodes.” There are different kinds of nodes, and there are many things you can

do with nodes to change the shape of the object. When you click on a node, you

are highlighting it and its appearance will change to show that highlighted

state. When the program sees that you have highlighted a node (or nodes) it will

change what it does with your input based on that fact. For example, using the

‘delete’ key on an object that has no nodes selected will delete that object.

However, if you have selected nodes, then the delete key will delete those

selected nodes.

Note:

You do not need to switch

modes to reshape an outline. You click an outline node to highlight it. If you

wish to work with the object as a whole, either ctrl-click the highlighted node,

or click off the object and then back on it. When none of an object’s nodes are

highlighted, you are able to move and re-size the object using the handles that

appear.

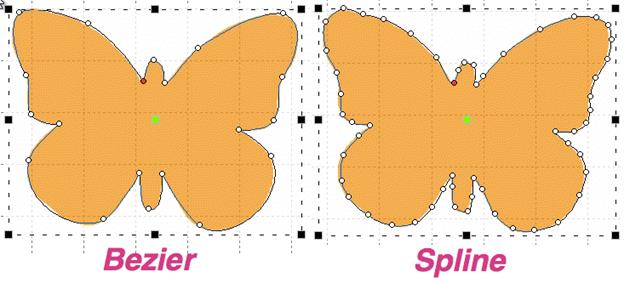

The underlying implementation of graphics in the platform uses

Bezier curves, named after the man who first made use of them to design car

bodies. Why do we use them here? Because the world has adopted these

annoying-but-useful little curves; and all drawing packages, CAD packages and

design software understands them, so there are a lot of people who have been

trained in their use. Are there better solutions? Well, yes, but let’s not get

into that right now, lest we upset the Math Police.

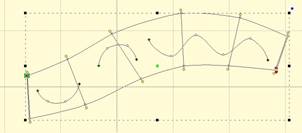

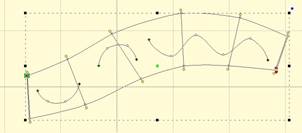

The idea of a Bezier curve is fairly simple. You have a start

point and an end point, and a curved line that runs in between them. If

you have a series of these, you can draw any kind of shape. The fun part is that

the curve between the two endpoints is controlled by two ‘Handles,’ one

connected to each node. In a simplified way, the first handle (which is

connected to the start point) will determine how the line will curve as it takes

off from the start. Likewise, the second handle will determine how the line

comes in to the end point.

The benefit to embroiderers using these curves is scalability;

Size does not matter. So, if you make a Run stitch object using a curve, those

stitches will generate nicely on that path at virtually any size, and the sewn

result will be a nice clean curve even when made large.

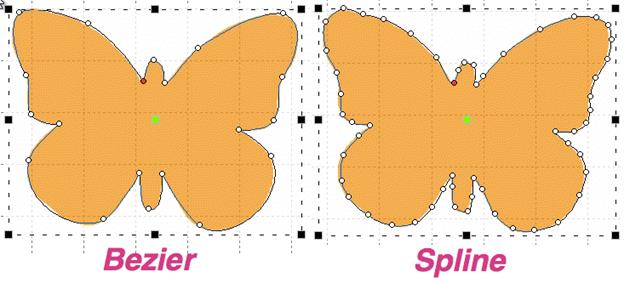

When

creating and editing outlines for shapes, you are always creating a Bezier form.

For beginners who are inexperienced with Bezier there exists an option to work

without “handles,” both when inputting a shape and when editing a shape. When

the Bezier handles are hidden on an object, you can edit the outline by moving,

adding and deleting nodes. This type of outline is known as a ‘spline’. The

limitation is that you cannot change the shape of the curve between outline

points. That is where the normal Bezier handles come in. You can switch any

object at any time between spline and Bezier, just be aware that when you go to

spline, your edits between nodes will be lost. Generally, we always recommend

that you learn the Bezier and we have made every attempt to ease you into

that.

When

creating and editing outlines for shapes, you are always creating a Bezier form.

For beginners who are inexperienced with Bezier there exists an option to work

without “handles,” both when inputting a shape and when editing a shape. When

the Bezier handles are hidden on an object, you can edit the outline by moving,

adding and deleting nodes. This type of outline is known as a ‘spline’. The

limitation is that you cannot change the shape of the curve between outline

points. That is where the normal Bezier handles come in. You can switch any

object at any time between spline and Bezier, just be aware that when you go to

spline, your edits between nodes will be lost. Generally, we always recommend

that you learn the Bezier and we have made every attempt to ease you into

that.

Note: If you want to quickly

reshape a Bezier curve but don’t understand the handles, we have added a feature

that lets you drag on the outline, between two nodes, and the outline will

follow your mouse, adjusting the handles automatically. This is also very handy

when you want to quickly draw with a very minimum of nodes, (very good for

re-sizing later).

‘Nodes’ and ‘Knots’ mean the same thing as used here, and that

is they refer to the outline points that are drawn and selectable.

Some things you can do with nodes on an outline:

• Select

a node by clicking on it.

• Edit

nodes by dragging them around.

• Add

nodes by double-clicking where you want one to appear, and you can double-click

a node to remove it.

• Drag

around a set of nodes, in which case you will select all the ones in your

“lasso”.

•

Right-click while nodes are selected and change properties and do other

things with the outline.

When a shape is

drawn, it goes from one node to another. It can either form a straight line to

the next node, or it can form a curve going ‘through’ that next node on its way

to the one that follows. The advantage of curves is that when you scale the

design up in size, the result is a nice smooth outline. If you draw with all

‘lines’, as many have done in the past, you are severely restricting the useful

size of the outline you are creating. For this reason, we normally draw with

curves, and you can switch to a line as you enter points (for example by holding

the ‘ctrl’ key) or you can do it after the design is created.

When a shape is

drawn, it goes from one node to another. It can either form a straight line to

the next node, or it can form a curve going ‘through’ that next node on its way

to the one that follows. The advantage of curves is that when you scale the

design up in size, the result is a nice smooth outline. If you draw with all

‘lines’, as many have done in the past, you are severely restricting the useful

size of the outline you are creating. For this reason, we normally draw with

curves, and you can switch to a line as you enter points (for example by holding

the ‘ctrl’ key) or you can do it after the design is created.

If you think about it, straight lines are not ‘natural’ except

in math; only people create things in the real world with perfectly straight

lines. So, curves and cusps are very useful, unless of course you are making a

geometric design.

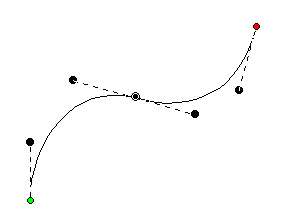

Notes: ‘Curved’ and ‘Line’

node types refer to the path coming toward the node. The path leaving the node

is controlled by the following node.

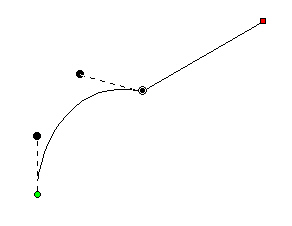

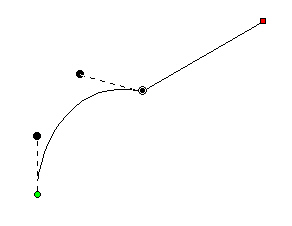

A ‘Cusp’ allows two

curves to go in different directions away from a common node, whereas a ‘Curved’

node creates a smooth line through the node, transitioning between the two

curves smoothly.

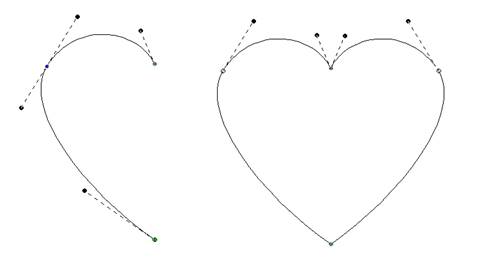

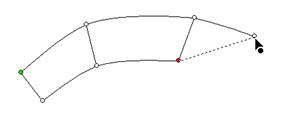

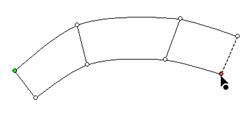

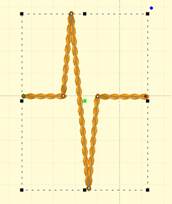

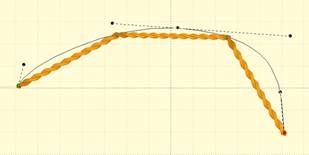

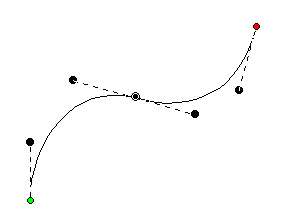

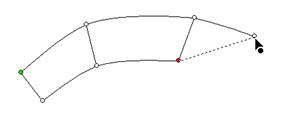

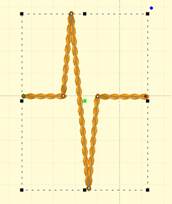

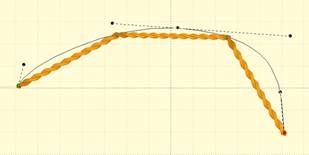

Here is an

example of a curved node in the middle, and a hard point at the end. See how the

path is a flat line going toward the final point. The path shape is defined by

the node it is going toward.

A straight line does not have handles. There is no need, as

there is nothing to adjust. If you want to make it curve, change the node

type.

On any path, there is a green node that indicates the start,

and a red node that indicates the end of the path. A closed shape will naturally

have the end positioned over the start, so it appears red.

If there are only two nodes in a path, you have a section. The

section can be a line or a curve, depending on the later node type. If you add a

third node at the end, and that one is also a curve, now you have a choice as to

what to do with the curve as it passes through the middle node. It can be

smooth-flowing, in which case the curve looks like one continuous line. Or, it

can be disjointed, making two distinct curves, in which case it is called a

‘Cusp’.

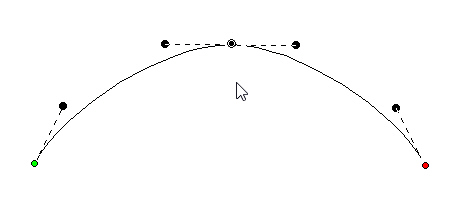

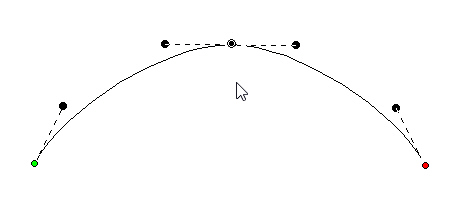

This image shows a selected curved node in the middle of a

3-node path; its handles coming in and going out indicate the travel of the

stitches. The handle coming in is in a line with the handle going out, thus the

curve is quite smooth at the node – it is almost like the node is not there,

other than to direct the path.

Remember, smooth curves are created by at least three nodes:

an initial starting node, a middle node that the curve runs through, and an

ending node. You can click a long smooth curve that runs though as many nodes in

the middle as you want, but naturally there’s always a start and an

end.

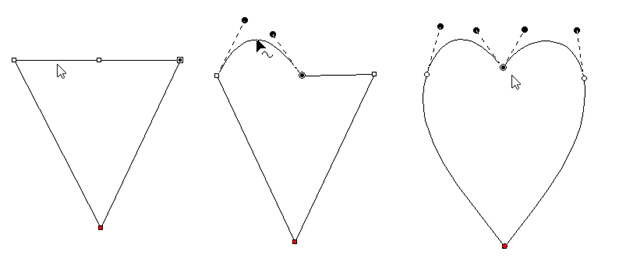

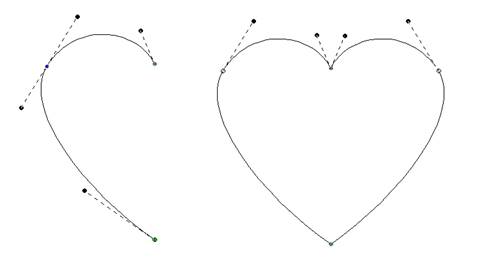

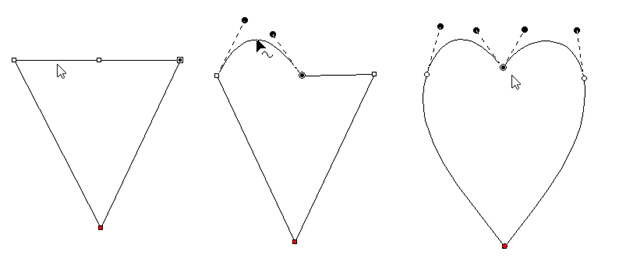

The alternative to a smooth curve is to have a node that comes

‘in’ from one direction, but leaves in another. This is a ‘cusp.’ Cusps are

important, as they make the hard turns where curvy bits intersect – such as the

top of a heart or in shapes of leaves, or almost anything in nature.

A cusp allows

you to have two curves come together on either side of a point. For instance,

the apex in the top, center of a heart-shape is a cusp. Traditionally digitizers

would make a curve that falls just short of the cusp and then make a line to the

cusp, and then they would begin a new curve going off to the other side. This

has the negative effect of that hard line being visible, especially when scaled.

It also produces a needle penetration where it isn’t needed. We’ll discuss more

on this later.

A cusp allows

you to have two curves come together on either side of a point. For instance,

the apex in the top, center of a heart-shape is a cusp. Traditionally digitizers

would make a curve that falls just short of the cusp and then make a line to the

cusp, and then they would begin a new curve going off to the other side. This

has the negative effect of that hard line being visible, especially when scaled.

It also produces a needle penetration where it isn’t needed. We’ll discuss more

on this later.

Use nodes where the path switches from turning left-to-right

or vice versa. And then when turning, place a node at the ‘widest’ point in the

turn if you need an additional node. This will yield the fewest number of nodes

needed to make the shape. Remember you can add nodes later, or adjust the

curves, if you need to refine the shape.

It is good to use minimal nodes to complete your shape, and

then go back and edit the curves to get the shape you want. The result will be a

nicer object shape and better embroidery. It takes practice, but you’ll find

that you can quickly analyze a shape and create it in very few clicks, and then

the edits required will be much easier.

Normally in graphics a “Closed” shape or outline means that

its start and its end meet up visibly. A shape that is closed can contain

stitches within, and can also have “holes.”

When

drawing a shape for embroidery, you may wish to have the end-point meet up with

the start-point without calling the shape “Closed.” For this purpose, there is a

button on the tool pane that lets you specify that a shape is closed or not.

Only closed shapes can contain holes.

When

drawing a shape for embroidery, you may wish to have the end-point meet up with

the start-point without calling the shape “Closed.” For this purpose, there is a

button on the tool pane that lets you specify that a shape is closed or not.

Only closed shapes can contain holes.

You can open an outline by clicking the ‘Close/Open Outline’

button up. You will not see a change in the shape, but you can now move the head

and tail nodes away from each other. The tail node will be red.

If you have a node selected when you open the outline, that

node becomes the new head/tail of the outline.

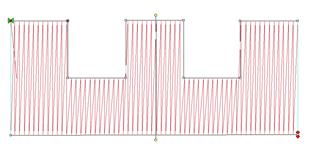

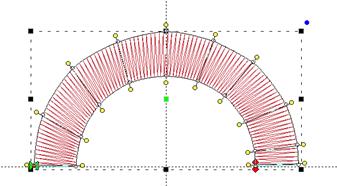

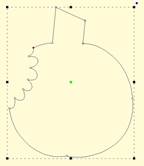

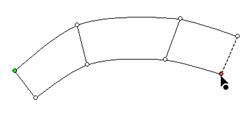

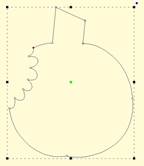

Oftentimes a drawing needs to be perfectly symmetrical. In

this case the first side of the drawing can be made, and the completion can be

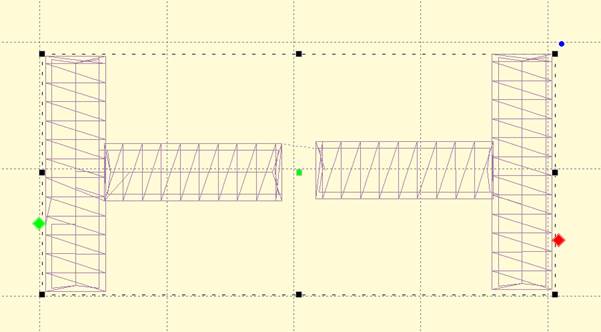

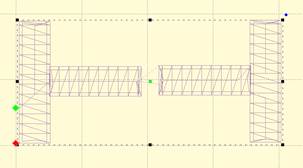

done automatically using the menu Create>Outlines>Complete Symmetric.

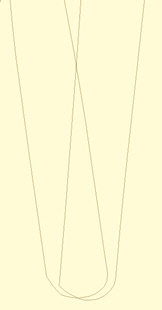

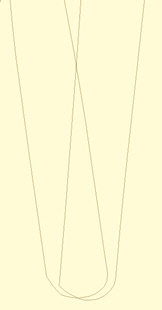

Left: First half

drawn, Right: After Complete Symmetric

Point Input

The Point Input method is the most commonly used method, and

for most people, it is the easiest. Click the Point button in the Tool Pane and

then start clicking along the line you wish to make.

As you

create your shape, you can create curved nodes with a normal left-click, line

nodes are made by holding the ‘Ctrl’ key during a left click, and cusps are made

by holding the ‘Shift’ key down during a left click.

As you

create your shape, you can create curved nodes with a normal left-click, line

nodes are made by holding the ‘Ctrl’ key during a left click, and cusps are made

by holding the ‘Shift’ key down during a left click.

You can use the ‘backspace’ or ‘Delete’ to remove points you

have entered. You can cancel the drawing using the ‘Esc’ or ‘Escape’ key.

When you have completed your shape, you can end it by

right-clicking. If you wish to end the shape and also close the outline at the

same time, hold the ‘ctrl’ key while right clicking.

While entering points along the outline, you do not need to

worry about the Bezier handles – they are created for you using some

‘reasonable’ values. Once you have created your shape, if you want to adjust the

handles, you can. Or you can ignore them entirely if you prefer. We’ll talk

about that shortly, in the ‘Editing Outlines’ section, subtitled “Working as

Spline/Bezier”

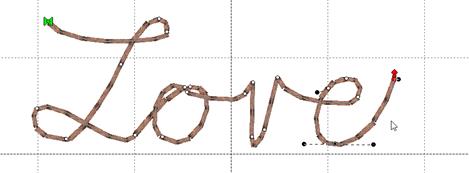

This

sounds like the most fun input method, and it is, but it is far from accurate.

The freehand input lets you doodle. You hold the mouse down and drag around.

Where you went gets smoothed out and turned into a curving path. You can click

for a line to a point, and then drag along some more. You can drag and release

any number of times to create lengthy and intricate paths if you wish.

This

sounds like the most fun input method, and it is, but it is far from accurate.

The freehand input lets you doodle. You hold the mouse down and drag around.

Where you went gets smoothed out and turned into a curving path. You can click

for a line to a point, and then drag along some more. You can drag and release

any number of times to create lengthy and intricate paths if you wish.

This is useful in practicality only with the Run stitch type.

Drawing freehand on a computer requires practice, and the more fluid your input

is, the better the result will be. Do expect to spend some time cleaning up your

handwriting!

As with other input methods, right-click to end your

input. Holding the ‘Ctrl’ key when right-clicking will close the

shape.

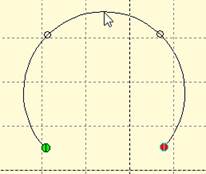

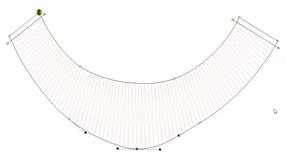

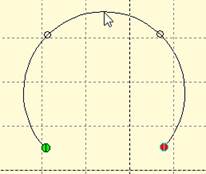

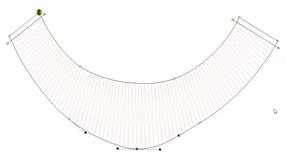

Arc Input

When you

want to create a curve that is perfectly circular, the Arc input can help. This

input uses three points, clicked with the mouse, to create the arc. The first

and second inputs should be on the arc that you want to create. After the second

click, moving the mouse will draw a circular arc between those first two points,

running through your mouse cursor. Once you have the desired arc, click the

mouse a third time, which ends the arc input.

When you

want to create a curve that is perfectly circular, the Arc input can help. This

input uses three points, clicked with the mouse, to create the arc. The first

and second inputs should be on the arc that you want to create. After the second

click, moving the mouse will draw a circular arc between those first two points,

running through your mouse cursor. Once you have the desired arc, click the

mouse a third time, which ends the arc input.

This program, like most drawing programs, allows Bezier forms

to take up to 90 degrees per node. If the circular arc you create goes around

more than a quarter of a circle, multiple nodes will be added.

You can edit the nodes which the arc input creates as you

would any other.

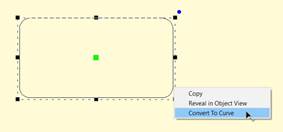

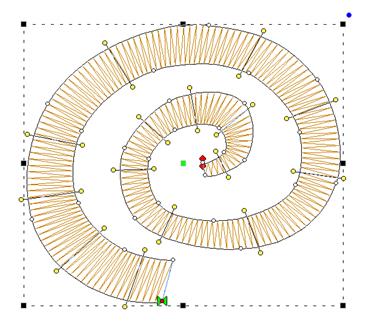

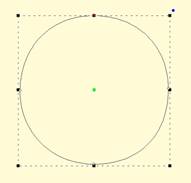

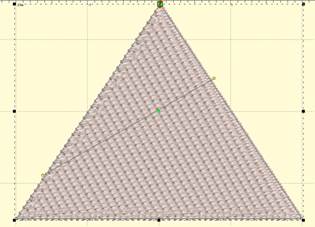

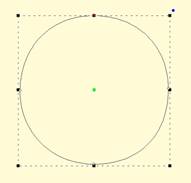

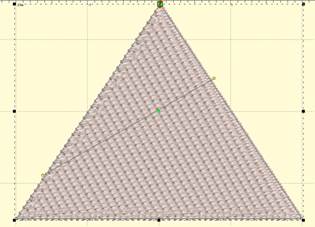

Shapes Input

The Shape

button activates a mode that creates a shape by dragging the mouse on the design

page. The down-pointing arrow next to the image on the button makes the shape

selection panel appear.

The Shape

button activates a mode that creates a shape by dragging the mouse on the design

page. The down-pointing arrow next to the image on the button makes the shape

selection panel appear.

To change the shape, click on a button to select the shape

that the tool will create.

Click the shape button, and then drag on the design page. The

size and orientation (rotation) of the shape is controlled by the length and

direction of your drag. Let go of the mouse button and the shape will appear on

the page as a new object.

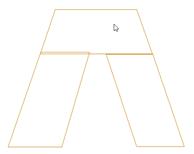

Shapes that might be useful in rectangular proportion, such as

rectangles and polygons, will follow the drag from the top, left diagonal corner

to the bottom, right corner. If you wish to make things perfectly square, hold

the Shift key down while dragging.

Some shapes have properties to adjust details of the shape,

such as corner roundness, number of corners, density of a spiral, etc.

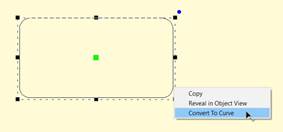

Shapes, as objects, have these special properties for the life

of the shape and can be adjusted at any time. The shape’s outline can be edited

by converting the shape to an outline. Right-click on a selected shape and

choose ‘Convert to Curve.’

Whether it is used as a shape or converted to a curve, the

object can have stitches applied.

The

professional graphics industry has adopted this method of input and it takes

getting used to. Select the Bezier Input method using the button on the Tool

Pane. To begin, click and drag. This will create an initial Node and a Bezier

handle. The next time you click and drag, you will be creating the points needed

to complete a Bezier curve section, and also begin the next one.

The

professional graphics industry has adopted this method of input and it takes

getting used to. Select the Bezier Input method using the button on the Tool

Pane. To begin, click and drag. This will create an initial Node and a Bezier

handle. The next time you click and drag, you will be creating the points needed

to complete a Bezier curve section, and also begin the next one.

If you simply click, you will create a flat curve – a line.

To create a cusp, hold the ‘ctrl’ key down when you click and

drag.

Right-click to end your input. Holding the ‘Ctrl’ key

when right-clicking will close the shape.

We have made the editing of outlines work in two modes, Bezier

and Spline. To understand spline, imagine something flexible, but with a little

bit of spring to it – in the original context a spline was a light piece of wood

that could be shaped around things. In this use, it is a line that flexes around

‘Nodes’ on the screen (where you have clicked). The more clicks you give, the

tighter the spline will have to bend in order to conform to the shape you

want.

Bezier lets you adjust the curves using handles, as we have

discussed. Now you get to decide how you will perform your edits.

The

Spline/Bezier button on the Tool Pane will toggle all the selected objects to

either show their handles, or hide them. Remember, if you switch handles off,

the outline will change to its automatic shape, and you may have to add some

nodes in order to recover the curves. Spline mode will almost always require

more nodes than Bezier.

The

Spline/Bezier button on the Tool Pane will toggle all the selected objects to

either show their handles, or hide them. Remember, if you switch handles off,

the outline will change to its automatic shape, and you may have to add some

nodes in order to recover the curves. Spline mode will almost always require

more nodes than Bezier.

If no objects are selected, this button also sets how your

next objects will be treated, once drawn. This button also acts as a program

preference, so if you choose to always work with Bezier, the next time you run

the program this will determine the state in which you start.

You can select a node by clicking on it. You can use the Ctrl

key while clicking to select multiple nodes. If a selected node is clicked with

the Ctrl key it will be de-selected, as is typical with virtually all computer

systems.

You can also select nodes by dragging around them. First,

select the object that you would like to edit. Then drag around the nodes you

want. When you release your mouse button, the nodes inside the area you dragged

will be selected.

You can also operate on holes, carving lines and breaklines in

this manner – drag around the nodes you wish to adjust.

Double click on the outline to insert a node. Double click on

a node to remove it. If you have a node or nodes selected, you can also use the

‘Delete’ key to remove them.

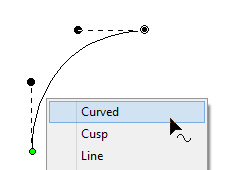

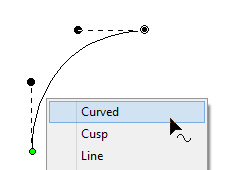

You can switch the type of any selected nodes by

right-clicking, which will bring up a pop-up menu. The node types are Curve,

Line and Cusp, as we have discussed. Remember that a curve will allow stitches

to pass through it without forcing the needle to stop at the node, but by

necessity of the shape, lines and cusps will cause the needle to land on those

nodes.

Sometimes an inclination line will be made very near a node.

If that node is moved so that the inclination line is left in empty space, the

incline will be removed automatically. We suggest you adjust your outlines

first, then go back and add and adjust your inclination lines.

Spline mode has the ability to insert and remove nodes to

adjust the shape. If the curve is too far away from the outline you want, simply

add more points on the outline where the shape you have is ‘most different’ or

furthest away from the artwork.

It is often best to begin with minimal nodes in the outline,

only basically representing the shape you are drawing. Then, go back and insert

only the nodes that are needed to pull the outline into shape. Doing it this

way, you will use a minimum of nodes.

Why use a minimum of nodes? The stitches being generated have

to look at all the nodes on your shape. If you insert hard nodes or cusps, the

needle will penetrate at those nodes, so you get less desirable embroidery and

an increased stitch count. Another reason to use minimal nodes is for editing

purposes. Suppose you test sew your design and realize you need move overlap for

registration issues – the fewer nodes, the easier and faster the edits can be

accomplished.

Editing paths with Bezier handles exposed is not hard, and is

very intuitive once you get past the first few minutes or so.

Editing is accomplished by dragging the handles, which adjusts

the curve as you drag. You can also drag the outline itself into place, which

will adjust the handles for you. When dragging the outline, the closer you are

to a node, the more that node’s handle will be adjusted, rather than the one you

are farther away from. Because this can make your handles go ‘wild’ we do not

let the outline drag if you grabbed it within 5% of the ends of the outline in

either direction. It is best to grab the curve somewhere in the middle and drag

it, then adjust the handles to perfect the shape.

Note:

Sometimes art will have the

handles ‘hidden’ under the nodes. Drag the outline and the handles will move,

exposing them so you can drag them around as needed.

Here’s a step-by-step example of making use of minimal nodes

while drawing, and good use of re-shaping: Make a heart, starting at the bottom,

using all Cusps (Shift key). You only need four points! Ctrl-right-click to

close the outline:

Next, hover your mouse over the curve in between the top left

two points as shown, and drag the curve up. You will see the shape beginning to

appear. Repeat the drag for the other side. In the example above, we’ve made the

sides smooth too. Do any editing desired for the overall image, and you have a

low-node-count shape that looks great!

There are also some tricks that we would like to share.

Trick 1: A favorite old movie of ours, Ghostbusters has

the line, “Don’t cross the streams!” In the movie, it implied that ‘Bad Things’

could happen. What we’re saying here is, “Don’t cross the handles.” It’s not

that you cannot cross the handles – you can – but certain object types will not

understand what it is you’ve done. So, we discourage it.

Trick 2: Another thing to consider is that the handles should

generally be in the direction of the travel of the path. If you have your

handles pointing away from the travel of the stitches, then the stitches may do

a “Two-Step” which you might not want to happen.

Trick 3: Sometimes you will inadvertently wind up with a

handle hidden under the node it is attached to: it is a handle with no length.

You can recover these by mousing-down in the middle of the curve and dragging

the outline, which reorients the handles for the curve you are dragging. Once

the handles are exposed, you can position them as needed.

Trick 4: Use nodes where the path switches from turning

left-to-right or vice versa. And then when turning, place a node at the ‘widest’

point in the turn if you need an additional node. If you have extras, you can

delete those and adjust as desired.

When you have two or more lines that should be connected, use

the menu Create->Outline->Connect to make them into a single line. While

you are drawing, it can happen that you end the drawing before the outline is

fully created. You can simply create the rest of the line as a separate object,

then select both and connect them.

When connecting lines, the head and tail of the first line in

the sequence are preserved, and thereafter the lines that are being connected to

it will be reversed as needed to ensure the nearest connecting point. You do not

need to have your line endpoints adjacent, as a connecting line will be added

for you if needed.

When you create a line, there is a point where you started and

a point where you ended. If you wish to reverse the direction of points on the

line, use the menu Create->Outline->Reverse Points.

Generally, the outline order is not very important for the

creation of stitches. You may, however, want to use this when working on

connecting shapes you have made.

You can select two points across a closed outline and break

the outline into two using the context menu option ‘Break across’. This is

sometimes useful in logo or promotional designs, where you have original shapes,

but want to separate them and insert a word or other design element in

between.

If you have an open shape selected, with one or more nodes in

it selected, the context menu option, ‘Break at point’ will split the object

into multiple objects.

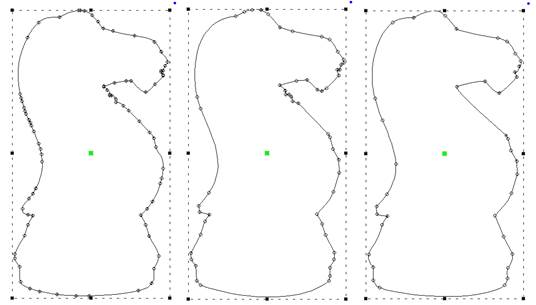

The menu Create > Outlines has Reconstruct Outlines to take

vector shapes and try to recreate them with fewer points. If you’ve brought in

something traced from a bitmap, it may have vector nodes every mm or so, making

an impossibly ugly outline. Copy and paste a new one directly over the original.

Sometimes it is useful to lock the original so as to avoid

selecting/moving/editing it by accident.

Reconstruct Outlines on the copy. This will reduce many nodes,

but they’ll probably not be exactly what you want. You can now edit, and even

reconstruct again, to get a clean vector shape. Use the original that you’ve

locked in place as a reference shape. Once your new shape is clean, delete the

original.

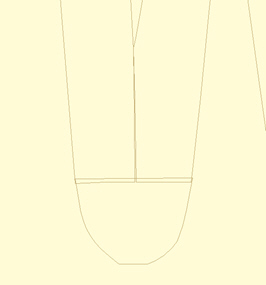

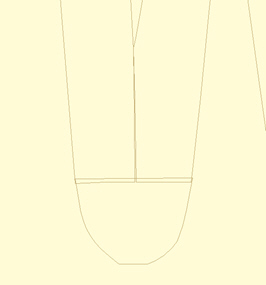

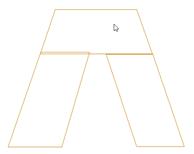

Left: original,

Middle: After Reconstruct, Right: With minor edits

Holes

Holes or

‘voids’ can be added to artwork for stitch types that use them such as

Fills.

Holes or

‘voids’ can be added to artwork for stitch types that use them such as

Fills.

In order to be able to add a hole to a shape it must not only

appear closed, but actually be closed. You can tell by looking at the ‘Close

outline’ button on the Tool Pane when the object is selected. If the button

appears depressed, the shape is closed. If not, you can click the button to

close the shape.

Not all stitch types allow holes. When it is allowed, the ‘Add

Hole’ button on the Tool Pane will be enabled. You can push this button and then

begin drawing the hole. Right click to complete your drawing as with any drawing

operation. To add another one, simply click the button again. There are no

limits to the number of voided areas (holes) that can be on a shape.

The hotkey for adding a hole to the currently selected object

is ‘o’.

If you have drawn several objects, or used path operations to

create them and you want to combine holes from multiple objects, select all the

objects and use the menu Create->Outline ->Combine Holes.

Holes can be removed by selecting a node on the hole and using

the right-click pop-up menu entry, “Delete Hole.” To remove all holes from an

object at once use the menu ‘Create->Delete Holes’.

Similarly, you can separate the hole into a new object, as an

outline, with the right-click pop-up menu entry, “Separate Hole.”

If you have multiple objects with original art that has holes,

but you would like to separate them out as individual objects, use the menu

Create->Outline->Separate Holes.

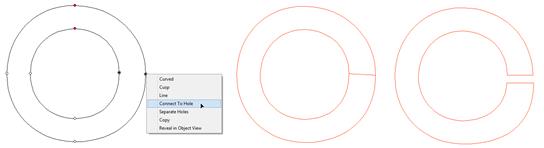

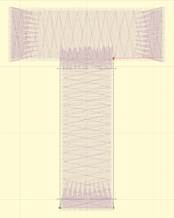

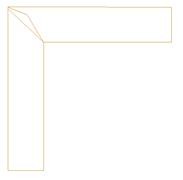

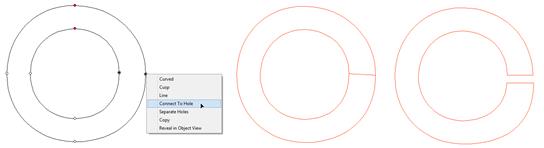

Connect to Hole

Sometimes you’ll need to turn a shape with a hole into a

continuous outline, such as to make a satin stitch. To accomplish this, select

two near points, one on the outline and one on the hole. Then use the context

item, ‘Connect to hole.’ The hole is now part of the outline, as shown:

Delete Holes (Level 2)

The menu Create > Outlines has a convenience command to

remove all the holes from an object in one step.

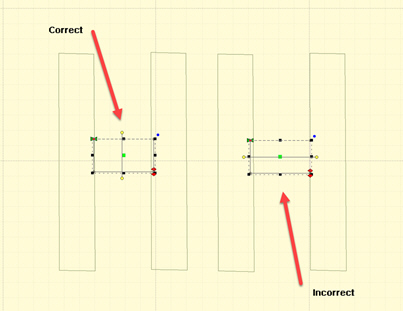

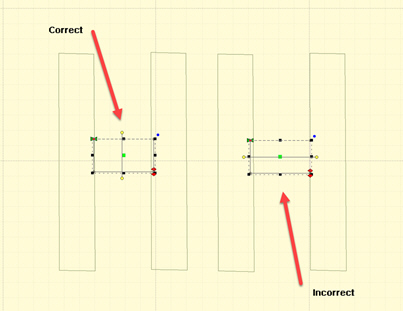

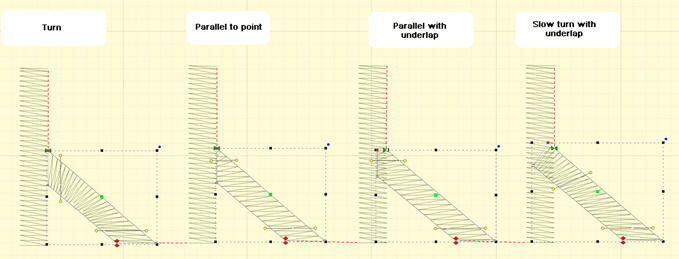

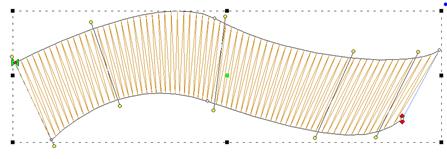

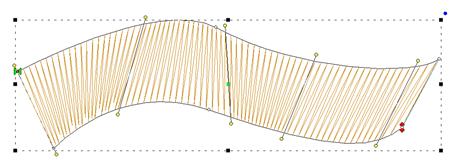

While not directly used in defining a shape itself, there are

Entry and Exit points that accompany outlines once a stitch object type has been

assigned.

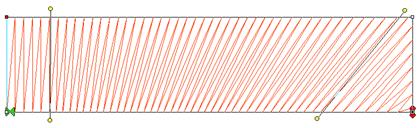

These Entry and Exit points indicate the preferred location of

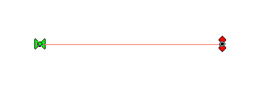

the beginning and ending of the stitching process. In the illustration, the

stitching would begin at the green handle on the left, and finish up at the red

handle on the right. You can drag the handles around anywhere on the outline.

You cannot drag them to a hole, if the shape has one.

There are some object types where the stitching follows an

algorithm that comes back to a single point. Those object types are noted in

their respective sections. Entry and exit points are used to limit the

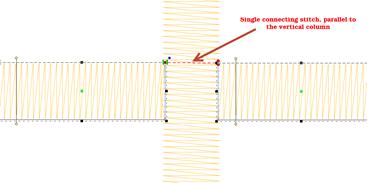

number of jump stitches in a design. By having the objects end and begin at

near-most points, the transition stitch between the objects is minimized.

The Entry point on an object is where the stitching will

begin, and Exit is where the stitching will complete. The purpose of adjusting

the entry and exit is to minimize (or eliminate) traveling runs needed to move

from one object to the next. This also lowers the stitch count.

Note: Usually you will want to set

the Entry and Exit points after you have sequenced your objects.

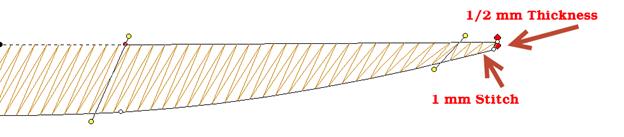

Most stitch generation has the availability of adjustable

Entry and Exit points, although some only use the Exit such as Stippling, where

stitching is continuous.

Entry and Exit adjustments are usually not noticeable in the

resulting stitches except for Runs. Runs by definition have styles such as

Single, Double, Bean, etc. When you have a single run enter and exit at the same

point, you are going to have a double-run result. The exit handle forces the

stitches to run to the exit, over top of what’s been stitched. This can be handy

when creating redwork or running-stitch designs as you may set the Exit Handle

as needed, and not worry about changing the property to a double.

Entry and Exit on a stitch object are controlled by the green

(Entry) and red (Exit) handles on the outline of the object. Drag the handles to

the point on the outline as desired. Generation of stitches is

automatic.

Use the menu Create->Auto Entry/Exit to set the Entry and

Exit handles on selected objects. The ‘Automatic’ process looks for the nearest

points on the objects if they don’t touch, or to a point where they touch, if

they do.

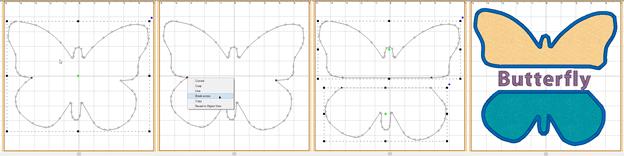

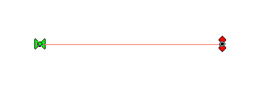

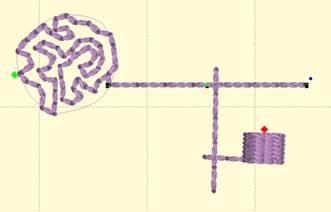

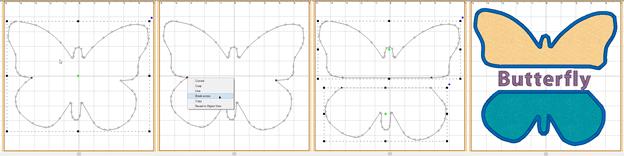

The Magic

Wand is a tool used to create outlines from bitmap images. There are two styles

– a wand for filled areas, and a wand for lines. The Line Wand tool is available

in Level 3.

The Magic

Wand is a tool used to create outlines from bitmap images. There are two styles

– a wand for filled areas, and a wand for lines. The Line Wand tool is available

in Level 3.

When you turn on the Magic Wand, you can click on the backdrop

image and the Wand will look at the color where you clicked, find all pixels

(dots) around it with a similar color, and then make an outline out of all of

those similarly-colored pixels. The shape that a Magic Wand creates will not be

as clean as one drawn by hand, but they are fully editable, and can be an

effective way to get started on some simple projects.

Note: When you like the wand

result, right-click to end the wand to keep what you’ve made. If you click the

Wand button again, or hit the ‘Esc’ key, you cancel the

operation.

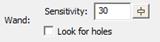

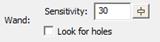

Because images differ in quality, when you click on the wand,

the Sensitivity controls will appear. A low number of sensitivity means the

pixels it is looking for will be very similar to the one on which you clicked.

If you have an image with a mottled texture, for instance a piece of scanned

fabric in the picture, you can make the sensitivity large, for example use 150,

and the outline will be expanded to include more pixels to get a better

outline.

As you adjust the sensitivity the wand will re-wand where you

clicked automatically. You do not need to click again.

Important: When you like the wand

result, right-click to end the wand and keep what you’ve made.

The wands will create as many objects or holes as you like.

Once your sensitivity has been adjusted and you have an outline you like, simply

click the wand again in another area to begin making a new object. Right-click

to end object creation once all objects have been wanded.

Expand the Object View to watch the objects get created –

sometimes a higher sensitivity will result in fewer objects or outline nodes,

which is desirable. Other times, higher sensitivity can add ‘noise’ in the edge,

or even fail to find a shape at all when the outline and background are

similar.

The first wand button creates an outline around areas filled

with a consistent color.

You can also use the wand during an ‘Add Hole’ operation.

Normal graphic fills, such as those from a cartoon image will

not need a high sensitivity to the color used. You can reasonably use the

default number. If the image is scanned from a print, you might need to increase

the sensitivity a little. Try different levels to see what you get. Note that

some large images with a high value for sensitivity can take longer to

wand.

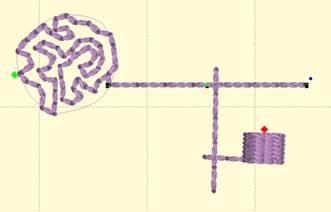

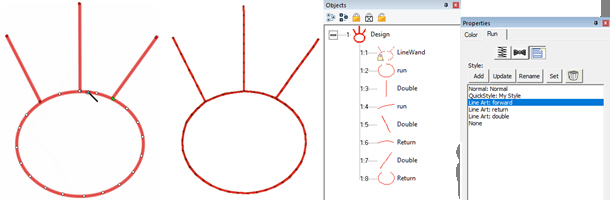

The second magic wand (Line Wand) is for line art drawings and

line art areas in a cartoon-style image. The color you click on has all of its

pixels gathered and thinned to make a running-stitch object. The line drawing

may be very complex, and the Line Wand will create as many objects as it needs

to to stitch around the entire design doubly. This is useful for automatic

outline or redwork designs. The wand will set all the Entry and Exits and create

a double-run design ready to sew.

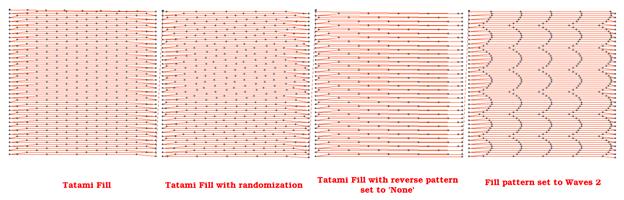

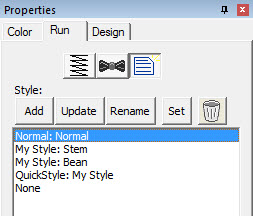

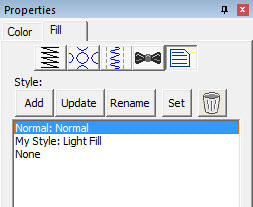

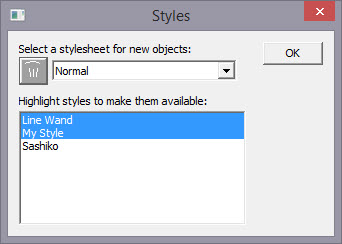

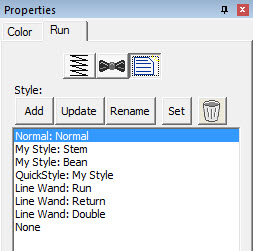

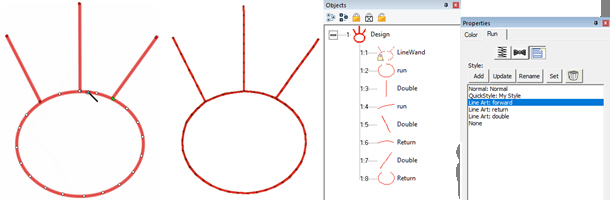

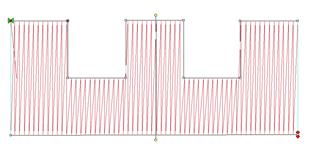

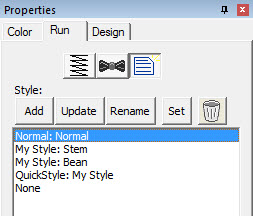

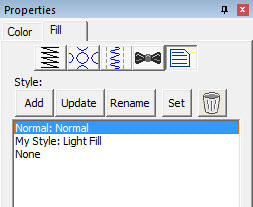

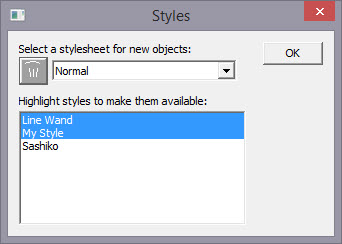

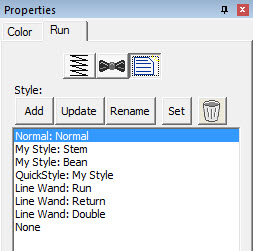

The objects that are created also have Styles used. You can